Therefore, when designing and constructing a home staircase of any type, it is necessary to proceed not only from considerations of convenience and safety, but also to think about its shape and appearance, that is, about the stairs. The principle of finishing and design of stairs In the design of stairs and when finishing stairs, a significant role is played not only by the type of component elements, but also by the arrangement of the external or inside structures with decorative materials, which ideally should also perform protective functions.

Now the time has come for interior decoration log house. The interior decoration of houses (baths) is no less important than their appearance. The cost of interior decoration of a house is quite high, so let's try to do some of the work ourselves.

wall decoration on the stairs- one of the important tasks when choosing a home decoration style. The internal staircase is the most important component of the room in which it is located, and the external one is an integral part of the exterior of the front part of the house.

4) Color scheme. Our eyes tend to stop and linger most on the walls, much more often than on the ceiling or floor. It is also necessary to take into account that color itself can have a huge effect on the fragile souls of our children. Moreover, this action can be both positive and negative. For example, red tones can cause an aggressive mood, black ones - generally depression! Many experts recommend that parents when choosing finishing materials choose pink, beige, green colors.

External and are a functional structure and the subject of traditional landscaping. The staircase can be made in a special way architectural style using a variety of building and finishing materials. At the same time, it is also a decorative element that creates a cozy home interior. To ensure the safety of movement on the stairs, an anti-slip corner for the steps is used. Step footrest thresholds made of various materials. A well-designed system that protects against slips and falls is the final preventative link in the design of a staircase.

Plastic anti-slip “mat” on the steps

Types of anti-slip coatings

The pads ensure stable movement safety, minimizing the risk of slipping and falling from the stairs. In addition, decorative overlays, including corner ones, improve the appearance of not only the staircase itself, but also harmonize the entire interior of the room. The trade assortment in specialized stores offers customers the following types of these useful devices:

- aluminum anti-slip pads;

- rubber protective pads;

- PVC linings;

- stainless steel linings;

- crumb rubber coating;

- corrugated rubber treads;

- self-adhesive rubber tape.

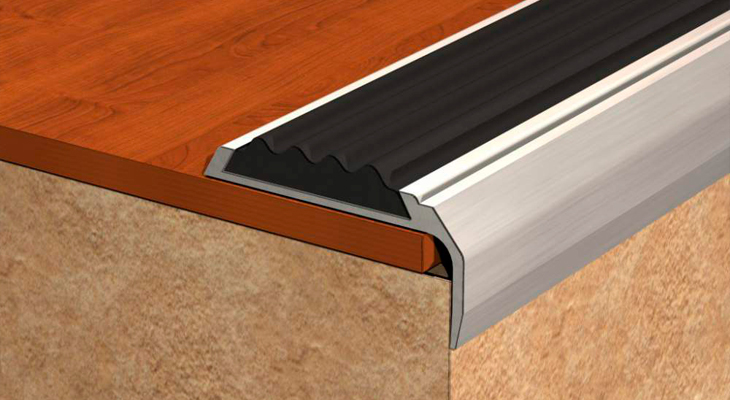

Aluminum step protection

Protective and at the same time anti-slip pads are aluminum profiles with a built-in ribbed rubber sheet in the middle. Such designs are flat or angular, protecting the thresholds of the steps and their edges from shock loads and chips. According to the recommendations of experts, a frame made of metal is the most optimal when equipping a protected and safe contact surface for staircase steps. For reliability, the corrugated rubber insert is glued to the aluminum frame with moisture-resistant contact adhesive. As the rubber wears out, it is easy to replace the worn elastic material with a new one.

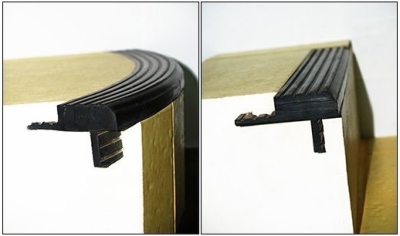

Rubber profile application technology

Equipping the edges of stairs with an anti-slip corner rubber profile is technologically recommended for capital stairs made of brick or concrete, the steps of which are lined with a fairly thin ceramic tiles(no more than 10 mm). It is often used when equipping anti-slip framing for the edges of radial stairs due to the flexibility of the material, unlike an aluminum profile. Installation of the corner rubber profile is quite simple - it is glued with glue to a cleaned and degreased surface.

In addition, flat rubber steps for stairs are glued to the steps in a standard way in accordance with the recommendations set out in the instructions and installation technology.

Plastic covers

PVC overlays are used mainly for landscaping and protecting the edges of steps from damage during interior spaces. PVC overlays are available for sale, both flat and typical - in the shape of corners for steps. An additional property of PVC linings is the improvement of visual aesthetic perception and decoration of the entire interior. They are made of elastic PVC material, which, when heated to 80 degrees, easily takes a given shape, including curved ones.

Corner and flat PVC overlays are very popular in everyday use, as they are wear-resistant, durable and relatively low in price, like aluminum materials.

A staircase is a dynamic and constructive element of the improvement of a building, cottage or city apartment, so it is necessary to provide for convenience, decorativeness, and guaranteed safety when using it.

There may be simple plastic covers, or there may be such beautiful LED panels

Anti-corrosion coating

Anti-slip profiles for lining thresholds for steps, made of stainless steel, are usually installed on entrance stairs (porch or ramp), at the entrance to the pool and shower room. This frame prevents slipping and lasts a very long time, as it is made of wear-resistant and anti-corrosion material.

Despite the fact that protective modules of this type belong to the high price segment, corner and flat anti-slip pads are very popular among builders and finishers. Thresholds on steps made of stainless steel are also functional and popular, just like aluminum ones, because they are practical, durable and have stable anti-vandal qualities.

Rubber treads

Anti-slip rubber treads (overhead steps) are installed mainly in areas of heavy traffic, on granite or steps, or steps lined with ceramic tiles. Rubber treads provide excellent fall protection, are wear-resistant and durable. They are produced by manufacturers in various shapes and sizes, several types of colors, and with a variety of corrugation patterns.

Additionally, these mats perform the function of barrier protection and cleaning from snow and dirt in winter period time, in places of average traffic intensity on the stairs.

Corrugated rubber pads - plates can be easily mounted on both indoor and outdoor stairs using double-sided tape. Treads enjoy consumer popularity, the same as PVC linings due to their low cost and availability.

European self-adhesive tape

Rough self-adhesive tape meets all the necessary requirements for such products, but is distinguished by its simplicity and ease of installation. The top layer of the tape is made of an abrasive material, which gives it an anti-slip quality. The standard thickness of the tape does not exceed 1 mm with a width of 25 or 50 mm, which is very convenient when installing this element at the entrance to a building or room where, due to the location of the door, it is not possible to lay a regular barrier mat. The protective frame of the edge of the step, in the form of a barrier tape, is perfectly mounted on internal stairs, ensuring comfortable movement along the stairs.

Rubber crumb coating

Specialist builders recommend equipping entrance staircases (porch or ramp) with thresholds and steps made of rubber crumb. This recycled material is made from shredded tires, a thickener component and a color additive. The covering rough material is produced in the form of tiles or seamless fabric, used for insulating protection of thresholds on steps.

In order to isolate the contact surface of the stair steps, a universal-shaped modular tile with a size of 50*50 cm and a height of 1 to 4 cm is purchased. Rubber crumb tiles can be easily cut in accordance with the existing configuration of the staircase and the corners for the steps.

On the one hand - very bright, on the other - safe covering of steps with rubber crumbs

Coverings and tiles made from rubber crumbs are quite in demand among consumers, as are aluminum profiles and PVC layers. The rough and elastic structure of the surface made from this finishing material meets all the necessary protective and anti-slip requirements. An anti-slip frame made from such tiles can be placed outdoors, as technical properties it can withstand temperature changes from -40 degrees to +80.

All types of finishing materials and ready-made protective structures, manufactured in a production manner and presented in the assortment of shopping centers, are certified. Guaranteed to meet all modern sanitary, hygienic and fire safety standards.

The description of ready-made structures and specialized finishing materials that can be used to equip an anti-slip and protective system for stairs is especially relevant. After carefully reading this article, the reader can finally choose a specific

Arrangement flight of stairs- quite a long process. You need to choose the right material and type of construction, stock up on all the necessary tools (you will need a saw, a hammer, a ladder square, a screwdriver, self-tapping screws, etc.). When the work is completed, it is necessary to evaluate the convenience and aesthetics of the design. Usually a frame is installed to give it a finished look - a corner for steps.

Multifunctional profile on the step

The aluminum profile on the step performs several functions at once.

- Prevents slipping.

- Protects the outer edges of steps from destruction.

- Fixes the facing material.

- In some cases, corners play the role of decoration.

An anti-slip corner is used when arranging external stairs and flights with high traffic. It is made from different materials, aluminum and brass are often used. To achieve maximum anti-slip effect, the corner is supplemented with a rubber insert, which is replaced at the end of its service life.

For steps, not only a corner is used, but also pads. If the corner is attached to the edge of the step, then the overlay is attached to its surface. This device can be produced in the form of a rubber band or can be an aluminum profile with a rubber insert. They are also suitable for external flights and stairs in public buildings with high traffic. An additional function of the lining is to protect the step surface from abrasion.

Thresholds for protecting steps and fixing floor coverings

If a stair angle is needed to mark the steps, then special corner thresholds will be needed to protect the treads of the stairs. They can be made from different materials, including metal, wood and plastic. The last two materials are not particularly wear-resistant, so optimal solution– metal corner thresholds. Aluminum, stainless steel, and brass are used for their manufacture.

Aluminum corner threshold is used especially often. It is suitable both for protecting the corners of steps and for joining different floor coverings. Such corner thresholds prevent abrasive abrasion of the surface, and at finishing joints they protect the edges of the material from deformation. The areas most susceptible to mechanical loads are the areas in doorways.

Aluminum thresholds effectively protect the staircase from wear and make it decorative. Thanks to the profiled surface, the corner elements provide an anti-slip effect. Thresholds are presented without coating, as well as anodized and laminated products. Anodized aluminum is an imitation of gold or bronze, while laminated analogues are often made in a woody color scheme.

Decorative overlays on steps

Carpet overlays can be used as decoration. They are easier to install than a carpet, since they are small fragments of material mounted on the tread. In most cases, the carpet pad is fixed using a self-adhesive film.

Advice:

Carpet overlays will add comfort and protect the steps, but they are not very durable. In view of this, when choosing products, you should pay attention to the density of the material.

How to install an aluminum profile or corner on the stairs

Many types of protective devices for steps (carpet pads, rubber bands) are mounted using a self-adhesive film located on the back side. It is more difficult to install a part based on an aluminum profile. If installed correctly, the frame will be firmly fixed on the surface.

At the first stage, the frame must be adjusted to the size of the step. Having applied the profile, the corner aluminum element is cut with a special saw, and the excess rubber insert is removed with a knife. Mark on the cover and drill holes. If they are already provided, then you can immediately begin marking the steps. You need to make holes according to this marking. After treating the corner profile with silicone sealant, it is placed on the step, dowels are inserted into the mounting holes and securely secured with screws.

After the staircase structure has been installed, you need to think about framing the steps. To give the structure a finished look, you must use

After installing the stairs, you should also think about framing the steps. For these purposes, use a corner for the steps of the stairs.

What are corners made of?

The corner for fastening the steps of the stairs can be made of various materials, for example, plastic, aluminum, brass or wood. However, the most popular and frequently used is the aluminum profile.

What role does the stepped corner play?

An aluminum corner can perform several functions at once:

- ensures safety (anti-slip);

- protects the edges of steps from chipping and cracking;

- carries out fastening of facing material;

- sometimes the profile plays the role of a decorative element.

Important! It is worth noting that the profile, which acts as an anti-slip profile, is used only when arranging stairs that are located on the street.

In order to achieve maximum anti-slip effect, rubber corners are used on the steps of the stairs. Sun The bearings made of rubber are replaced with new ones at the end of their service life.

Attention! In addition to corners, you can also use overlays. The difference is that the corners are attached to the edge of the step, and the overlay is attached to its surface.

Both options (overlays and corners) can be used both for external stairs and for internal ones located in public places, for example in mall or a clinic.

Corner thresholds

Stair profiles are used to mark steps, and special corner thresholds are used to protect steps. They, like the corners, can be made of wood, metal or plastic.

Important aspect! A metal corner threshold (made from brass, steel or aluminum) is the most wear-resistant and reliable.

The most popular option is the aluminum corner threshold.

Features and characteristics of aluminum corner threshold:

- High wear resistance.

- Attractive appearance.

- Anti-slip effect (due to profiled surface).

- The coating can be laminated/anodized. The second option is presented in gold, bronze and chrome. Laminate coating can be presented in any color, but most often it imitates wood.

Methods for fastening the threshold:

- First method: external. This method is considered the most popular. Fastening is carried out using screws and dowels, pre-installed into the floor.

- Second method: hidden. The fastening process is much more complicated than the previous method. However, “hidden” looks much more attractive.

Types of aluminum thresholds:

- Floor-standing. This type is used if it is necessary to press the coating at the joints. The shape of the threshold depends on the type of coating (for example, the threshold can have a T-shaped, straight or radially curved shape).

- Overlays installed on the edges of steps. This type of threshold protects the step from mechanical damage.

- Thresholds of different levels. They are used when it is necessary to connect floor coverings of different heights.

It is worth noting that thresholds can be of different sizes (width, length), so choosing the right option will not be difficult.

Installation of corners

Most overlays designed for steps are installed using self-adhesive tape located on the back of the overlay.

The process of gluing the nozzle to the step:

- Before gluing the protective cap, it is necessary to treat the step. To do this, the surface should be cleaned of dust and dirt. Then wipe with a damp cloth.

- Determine the place where the tape will be attached.

Important! If there are irregularities and cracks, the surface must be primed.

- You must wait until the primer layer dries. Then you can begin installing the cover.

- Remove the protection (film) from the lining. It is worth noting that the film must be removed gradually, pressing it tightly to the intended location.

- After the overlay has been glued, it must be leveled. To do this, smooth it using a spatula in the direction from the middle to the edges.

As for caring for self-adhesive film, it does not require special cleaning. It is enough to periodically remove dust from it with a brush. It can also be washed with any detergent.

If the cover was installed according to the instructions, it will serve for quite a long time.

The process of attaching steel angles to staircase steps is much more complicated than gluing a self-adhesive attachment.

The process of attaching an angle (steel/aluminum) to a step:

- The profile is cut using a special saw. Excess pieces of the rubber insert are removed with scissors. So, the profile was adjusted to the size of the step.

- Marks are placed on the corner, along which holes are drilled. Then they put marks on the steps. Using a drill, make holes in the steps (according to the marks).

- The profile is treated with sealant.

- Place the treated corner on the step. Dowels are inserted into the space provided for fastening. They are secured with screws.

In order to install a corner for steps, you do not need special equipment. Therefore, you can carry out the installation yourself, the main thing is to have the desire.

If the corner was installed strictly following the instructions, then the staircase structure will not only be reliable, but it will also have an aesthetic appearance. It is also worth noting that the corner extends the life of the steps.