Having a milling machine really simplifies the work of inserting hinges, forming complex holes, recesses, wood carving, etc. But this does not mean at all that it is necessary to have professional and expensive equipment: it is enough to have a simple manual device.

The only thing you need is to be able to basicly handle wood and use power tools. In addition, you need to have a desire, otherwise without this there will never be a result. Those who have no desire to work simply buy furniture or hire craftsmen to, for example, install a new door and cut locks. Any work, especially with power tools, requires certain knowledge, and especially safety precautions.

The milling device is designed for processing both wood and metal. With its help, it is possible to form recesses or holes of any configuration. This greatly simplifies tasks such as inserting hinges and inserting locks. Doing this with a chisel and an electric drill is not so easy, and it takes a lot of time.

There are stationary milling devices and portable (manual). Hand-held electric milling machines are considered universal devices, with the help of which, in the presence of attachments, it is possible to perform operations for various purposes; you just need to change the position of the part in relation to the device or vice versa.

Stationary devices are used in factories or factories where mass production of wood or metal products is established. Under such conditions, the cutting attachment is stationary, and the workpiece moves along the desired path. When using a hand tool, on the contrary, the part is fixed motionless and only then it is processed, although there are parts that require fixing a hand tool. This is provided for in the design, therefore, it is considered more universal. This is especially true when a large number of parts need to be processed, and it is not possible to use a stationary machine.

A homemade milling machine is a horizontal platform with a hole in the center, to which a hand-held device is attached from below.

A homemade milling machine is a horizontal platform with a hole in the center, to which a hand-held device is attached from below. There are many types of milling machines, but for use at home or for starting your own business, universal models are more suitable. As a rule, they are equipped with a set of cutters and various devices for performing various types of operations. The only thing is that if you have a manual milling cutter, simple operations can take much longer than when using a stationary machine.

Using a manual milling device it is possible to:

- Make grooves or recesses of any shape (curly, rectangular, combined).

- Drill through and non-through holes.

- Process ends and edges of any configuration.

- Cut out complex shaped parts.

- Apply drawings or patterns to the surface of parts.

- Copy parts if necessary.

Copying parts is one of the functions of any electric milling machine.

Copying parts is one of the functions of any electric milling machine. The presence of such functions makes it possible to simplify the production of the same type of furniture or the production of identical parts not related to furniture production. This is one of the main advantages of this tool. As a rule, to produce parts of the same type, it is necessary to install copying machines, which are designed to perform only one operation, which is not always profitable, especially in small enterprises.

Getting started and caring for the tool

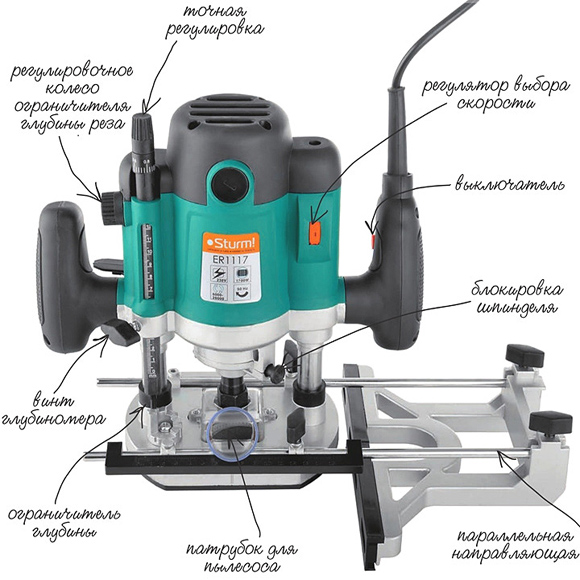

To understand how this device works, you should familiarize yourself with its main parts and their purpose.

Composition and purpose of main components

A manual milling device consists of a metal body and a motor, which is located in the same body. A shaft protrudes from the housing, onto which various collets are placed, serving as adapters. They allow you to install cutters of various sizes. The cutter is inserted directly into the collet, which is secured with a special bolt or button, which is provided on some models.

The main elements of a manual milling device and their purpose.

The main elements of a manual milling device and their purpose. The design of the milling device includes a metal platform, which has a rigid connection to the body. It is attached to the body by means of two rods. On the outside, the plate has a smooth coating that ensures smooth movement during operation.

The manual milling device has some characteristics that can be adjusted:

- Due to the handle and scale for adjusting the milling depth. Adjustment is carried out in 1/10 mm increments.

- By adjusting the rotation speed of the cutter.

At the initial stages, when mastering the tool, it is better to try to work at low or medium speeds. Although you should always remember that the higher the speed, the better the work. Especially if this concerns critical, visible areas that cannot be masked.

In addition to these levers, there is also a button to turn the product on and off, as well as a lock button. These elements are considered basic, ensuring high-quality and safe performance of work. There is also a parallel stop, which contributes to ease of use. It can be rigidly fixed or with the ability to adjust the shift of the working area away from the center.

Caring for a hand-held milling device

Usually, a factory product falls into the hands of a person tested and lubricated, so no additional measures should be taken. Only during its operation you need to monitor its cleanliness and serviceability. At the same time, it should be regularly cleaned of dust and the lubricant should be changed, if so written in the passport. Lubrication is especially necessary for moving parts. As an option, you can use aerosol lubricants, but you can also get by with regular ones, such as Litol. The use of thick lubricants is not recommended, as chips and dust stick to them. If aerosol lubricants are used, then this factor can be eliminated.

The sole, the smooth part of the body, also requires lubrication. Regular lubrication will ensure smooth movement.

Despite this, the purchased item should definitely be checked for quality of assembly and presence of lubricant.

Unfortunately, not all manufacturers, especially domestic ones, care about build quality. There are cases when, after the very first hours of operation, screws or screws are unscrewed from a product because they were not tightened properly.

Rotation speed adjustment

The operation of any tool is associated with certain conditions related, first of all, to the nature of the material being processed. It can be plywood, composite material or regular wood. Depending on this, the rotation speed on the electrical appliance is set. As a rule, the technical data sheet always indicates the operating parameters of the device, depending on the technical characteristics and characteristics of the surfaces being processed, as well as the cutters used.

Indicators of processing speeds when using various cutters.

Indicators of processing speeds when using various cutters. Fixing the cutter

The first thing the work begins with is installing and securing the cutter. At the same time, you should adhere to the basic rule - all work is performed with the cord plug removed from the socket.

The cutter is installed according to certain marks, and if they are missing, then to a depth of no less than * the length of the cutter itself. How to install a cutter on a specific model can be found in the instructions, which must be included in the technical documents for the device. The fact is that each model may have its own design features and it is not possible to talk about this in the article.

Installing the cutter on the device before starting work.

Installing the cutter on the device before starting work. There are both simple and more “advanced” models, as they say. Some models have a shaft rotation lock button, which makes installing the cutter easier. Some, especially expensive models, are equipped with ratchets. So it won’t be possible to specifically describe the process of installing the cutter, and it doesn’t make sense, since everyone who is familiar with the operation of such devices will figure it out in a moment.

Adjusting the milling depth

Each model has its own maximum milling depth. At the same time, it is not always the maximum depth that is required, but a certain depth that is set before work. Even if maximum depth is required, in order not to overload the device, the milling process is divided into several stages, changing the milling depth in steps. For adjustment, special stops are provided - limiters. Structurally, they are made in the form of a disk located under the bar, on which stops of various lengths are fixed. The number of such legs can be from three to seven, and this does not mean that the more there are, the better. It is better if it is possible to adjust each of the legs, even if their number is minimal. To secure this stop in the optimal position, you should use a lock in the form of a flag.

The process for adjusting the milling depth is as follows:

Thus, the workpiece is milled to a given depth.

Thus, the workpiece is milled to a given depth. On high-quality, expensive models there is a wheel for precise adjustment of the milling depth.

Using this wheel, you can more accurately set the depth without disturbing the previous setting.

Using this wheel, you can more accurately set the depth without disturbing the previous setting. This wheel (green in the photo above) allows you to adjust the depth within small limits.

Milling cutters for hand milling tools

A milling cutter is a cutting tool that can have an intricately shaped cutting edge. As a rule, all cutters are designed for rotational movements and therefore have a cylindrical shape. The shank of the cutter, which is clamped in the collet, has the same shape. Some cutters are equipped with a thrust roller, so that the distance between the cutting surface and the material being processed remains constant.

Milling cutters are made only from high-quality metals and their alloys. If you need to process soft wood, then HSS cutters will do, and if you need to process hard wood, then it is better to use cutters made of harder HM alloys.

Each cutter has its own technical characteristics, which provide it with high-quality and long-lasting work. The main indicator is the maximum speed of its rotation, which should never be overestimated, otherwise its breakdown is inevitable. If the cutter is dull, you should not try to sharpen it yourself. Sharpening of cutters is carried out using special, expensive equipment. After all, you need not only to sharpen the cutter, but also to maintain its shape, which is no less important. Therefore, if for some reason the cutter becomes dull, it will be cheaper to buy a new one.

The most popular cutters

There are cutters that are used in work more often than others. For example:

Groove molds are designed to create recesses in any location on the workpiece.

Groove molds are designed to create recesses in any location on the workpiece. There are cutters that are simple, monolithic, made from a single piece of metal, and there are typesetters. Set cutters consist of a shank, which serves as the basis for a set of cutting elements. By selecting cutting planes and installing them on the shank, using washers of various thicknesses, you can form an arbitrary relief on the surface of the workpiece.

A set cutter is a set of cutting surfaces and washers that allows you to assemble a cutter of the desired shape.

A set cutter is a set of cutting surfaces and washers that allows you to assemble a cutter of the desired shape. In fact, there are a lot of cutters and this is only a small fraction of what is produced. All cutters differ in the diameter of the shank, the diameter of the cutting surfaces, their height, the location of the knives, etc. As for manual milling equipment, it is enough to have a set of five of the most common cutters. If necessary, you can purchase them at any time.

Rules for working with hand milling tools

Working with power tools requires special rules, especially when there are rapidly rotating elements. In addition, as a result of work, chips are formed that fly in all directions. Despite the fact that most models are equipped with a protective shield, this does not fully protect against the flow of chips. Therefore, it is better to work with such a tool wearing safety glasses.

The photo shows a model where a vacuum cleaner is connected to remove chips.

The photo shows a model where a vacuum cleaner is connected to remove chips. General requirements

If you follow the basic requirements for safe work with an electric hand router, the end result will please you with the quality of work and a safe outcome. These are the conditions:

The requirements are not very complex and quite feasible, but to ignore them means putting yourself in danger. And one more thing, no less important, is the ability to hold a milling tool in your hands and feel how it works. If serious vibrations are felt, then you need to stop and analyze the reasons. It is possible that the cutter is dull or there is a knot. Sometimes it is necessary to correctly set the rotation speed of the cutter. Here you can experiment: either add speed or reduce it.

Edge processing: using templates

It is better to process the edges of a wooden board using a surface planer. If this is not possible, then you can use a hand router, although this will take some time. These works are carried out both without a template and with a template. If there are no skills or very few of them, then it is better to use a template. For processing edges, straight edge cutters are used, both with one bearing at the end of the cutting part and with a bearing at the beginning (see photo).

Edge cutters.

Edge cutters. You can use an already processed board or other flat object as a template. Moreover, the length of the template must be greater than the length of the workpiece, both at the beginning and at the end of the workpiece being processed. This will avoid unevenness at the beginning of the edge and at the end. The most important thing here is that the template or object acting as a template has a smooth and even surface. In addition, its thickness should not be greater than the gap located between the bearing and the cutting part.

The width of the part is less than the length of the cutting part

Moreover, the longer the cutting part, the more difficult it is to work with the tool, since more effort is required. In this regard, it is better to start working with cutters that have an average length of the cutting part. The operating principle for edge processing is as follows:

- The template is attached so that it is at the desired height and has a flat horizontal surface.

- The template is firmly mounted to a table or other surface.

- The cutter with the roller is installed so that the roller moves along the template, and the cutter (cutting part) moves along the workpiece. To do this, perform all the necessary manipulations with the template, workpiece and tool.

- The cutter is installed in the working position and clamped.

- After this, the tool turns on and moves along the template. In this case, you should decide on the speed of movement, which is determined by the depth of processing.

- The milling unit can be either pushed or pulled, depending on what is convenient for you.

After the first pass, you should stop and evaluate the quality of the work. If necessary, another pass can be made by adjusting the position of the tool. If the quality is satisfactory, then the clamps are removed, freeing the workpiece.

Using this approach, it is possible to remove a quarter along the edge or in some of its parts. This is done by setting the cutting edge so that it extends to the required depth into the part.

Quarter shot on a furniture façade.

Quarter shot on a furniture façade. If you replace the cutter with a shaped one and move the guide, as well as use a stop, you can actually apply a longitudinal pattern to the part (pictured below).

Applying a longitudinal figured pattern to the workpiece.

Applying a longitudinal figured pattern to the workpiece. If you use a similar milling technique (with a template), you can easily master the technique of working with wood in general. After some time, you can abandon the templates, since their installation takes a lot of useful time.

How to make a straight edge without a template: you can’t do this without experience.

How to make a straight edge without a template: you can’t do this without experience. The width of the part is greater than the length of the cutting part

Quite often, the thickness of the workpiece is greater than the length of the cutting part of the cutter. In this case proceed as follows:

- After the first pass, the template is removed and another pass is made. In this case, the template will be the already processed part. To do this, the bearing is guided along the machined surface. If the cutting part was again missing, you will have to make another pass.

- For final processing, you should take a cutter with a bearing at the end, and the workpiece should be turned upside down, after which it is secured with clamps. As a result, the bearing will move along the machined surface. This approach makes it possible to process thick parts.

The bearing is guided along the machined surface, and the cutting edge processes the rest of the workpiece.

The bearing is guided along the machined surface, and the cutting edge processes the rest of the workpiece. In order to master the work of a hand milling tool, you will need a lot of rough blanks, which you don’t mind throwing away later. No one succeeded the first time. To achieve anything, you need to train hard.

Achieving Various Shaped Edges

If a figured edge is required, which is most likely necessary, then first pay attention to the condition of this edge. If it is uneven, then you will have to level it and only then begin to form a curved edge by selecting the appropriate cutter.

Rounded edge.

Rounded edge. It is necessary to prepare the surface so that the cutter does not copy the curvature along which the roller will move. In this case, a sequence of actions is needed, otherwise a positive result will not work.

Making wooden products at home is a good business, but first you need to buy specialized materials and equipment. A milling machine is a power tool, without which it is difficult to process wood, especially if there is no set of cutters available that allow you to create diverse and multifunctional products. It is important to choose the right model, which will be equipped with all the accessories.

There is nothing difficult in assembling a cutter yourself if you follow the step-by-step instructions. In addition, even a novice master will be able to equip the mechanism with all the necessary functions and auxiliary systems. For example, a holding system, without which it would be impossible to work. The movement of a rotating cutter is chaotic during the processing of wooden parts, which leads to strong vibration that a master cannot compensate for even with excellent physical training. Additional fixing and guiding devices are responsible for the secure installation of the device.

When purchasing this equipment, all guides and fixing elements are included in its complex, but they perform only simple working movements, which are not enough for high-quality and beautiful processing of wooden products. Complex work processes require the purchase of additional holding templates, which cost a lot of money, but it is easy to make such wood router devices with your own hands.

When purchasing this equipment, all guides and fixing elements are included in its complex, but they perform only simple working movements, which are not enough for high-quality and beautiful processing of wooden products. Complex work processes require the purchase of additional holding templates, which cost a lot of money, but it is easy to make such wood router devices with your own hands.

Many specialists prefer to use drawings when assembling a restraint system, but this is wrong. It is better to initially understand the design of the machine and carry out independent calculations that will satisfy all the necessary requirements. At the same time, the efficiency and reliability of such structures will be better, and this is not to mention the knowledge of the design, which the master can repair independently at any time.

There is a wide variety of accessories that increase the functionality of a milling machine. Among them are:

- parallel stop;

- guide bar;

- compass;

- copy sleeve;

- templates;

- nozzles

The design of the rip fence for a router table is the simplest of all types of holding systems. Making it yourself will not be difficult if you first understand the principle of its operation.

To begin with, select an object that will serve as an emphasis. This can be an oblong product that can easily be connected to a fixed rod. Next, select a guide plane along which the router constantly moves. In some cases, instead of a guide element, the flat side of the workpiece is chosen. This part must be smooth and even so that it can slide freely along it.

To begin with, select an object that will serve as an emphasis. This can be an oblong product that can easily be connected to a fixed rod. Next, select a guide plane along which the router constantly moves. In some cases, instead of a guide element, the flat side of the workpiece is chosen. This part must be smooth and even so that it can slide freely along it.

For normal movement of the cutter using the workpiece guide, a control groove is first made in it and the distance from the edge to the zero mark is measured. As a result, it is easy to move the stop along the rod, setting any acceptable distance, but it is important to remember that when working with two rods, they must be fixed at the same time.

The rip fence is a unique attachment that is great for edging, quartering, or routing grooves. It is used to cut workpieces according to the width specified in the settings or process round-shaped parts. To process products with a rounded surface, a special gasket with an obtuse angle is installed between the stop and the end of the workpiece. Such a device is more useful than a jigsaw, which creates many defects and defects during operation. For example, when sawing wooden workpieces to width with a jigsaw, the cut turns out to be crooked.

The principle of operation of the guide bar is similar to the thrust jig, but there are significant differences that make this mechanism more preferable for operation. The rip fence only performs directional movements, unlike the guide bar, which allows you to select the angle for processing wooden products.

You can achieve the ability to choose the angle of movement of the cutter by installing a clamp or suction cups. It’s easy to make this option yourself using corners of a suitable size or profile. For example, an old curtain rod is perfect as a base. In this matter, the main thing is to create conditions for the free movement of the carriage in the direction of the guide and secure it stably by using two rods, and not one. Sometimes the width of the workpiece exceeds the parameters of the rip fence and therefore using a guide bar is the best option.

You can achieve the ability to choose the angle of movement of the cutter by installing a clamp or suction cups. It’s easy to make this option yourself using corners of a suitable size or profile. For example, an old curtain rod is perfect as a base. In this matter, the main thing is to create conditions for the free movement of the carriage in the direction of the guide and secure it stably by using two rods, and not one. Sometimes the width of the workpiece exceeds the parameters of the rip fence and therefore using a guide bar is the best option.

If work is required that requires milling grooves along a broken line or cutting an edge with a curved path, then a guide rail can easily cope with this. To do this, you need to stop the router at the breaking point, loosen the guide and turn the guide to the side at a given angle. During the process of changing the angle, the cutter remains in its place, representing the axis of rotation. Then the cutter is fixed again in the new specified position, and milling work continues.

There are also the most advanced models that can change the vertical direction. This method of processing wooden parts significantly expands functionality.

The purpose of the compass installed on a milling machine is known to many specialists in this field. With its help, circles can be easily cut from wooden blanks. The principle of its operation is similar to a simple compass, but there are some features.

The guide rod is one of the main elements that acts as a compass leg and has grooves or special plates with calibrated holes that allow you to reconfigure and set the desired diameter. The router guide is at the other end of the stud. The entire structure moves around a fixed pin, which stands in the center.

Factory models differ only in the diameter adjustment device. To do this, use a hinge with two rods to increase the stability of the craft, support platforms, plates or calibration of holes.

Factory models differ only in the diameter adjustment device. To do this, use a hinge with two rods to increase the stability of the craft, support platforms, plates or calibration of holes.

You can assemble homemade equipment if you use any durable and smooth material. Many craftsmen use textolite for this. When assembling, you need to remember about the reliable fixation system, which helps to do the job with the highest quality. Cutting a circle is difficult and it is simply impossible to correct errors as a result. That is why vibration of the structure must be minimized to prevent the equipment from moving during the cutting process. To attach the cutter to the device, special holes must be provided and grooves for moving the carriage with a fixing device must be cut.

A compass on a cutter for cutting circles is the simplest model, the functionality of which can be easily expanded if you use a support with a cross groove system. This option allows you to cut ovals by constantly moving the grooves, which form an even figure. This tool cuts ovals next to and around the nozzle, all thanks to a wide choice of cutter paths.

This element of the milling machine belongs to a new generation of systems that significantly simplify work and expand the functionality of the equipment. A copying sleeve is needed in cases where it is necessary to cut out a complex design on a workpiece or make the same cut on several products. In some cases, it is necessary to cut door hinges or similar parts into a piece of wood. For the convenience of performing such work, you need to learn in advance how to make a template for a router and only then begin its production. One of the most common patterns is the tenon cutter.

This element of the milling machine belongs to a new generation of systems that significantly simplify work and expand the functionality of the equipment. A copying sleeve is needed in cases where it is necessary to cut out a complex design on a workpiece or make the same cut on several products. In some cases, it is necessary to cut door hinges or similar parts into a piece of wood. For the convenience of performing such work, you need to learn in advance how to make a template for a router and only then begin its production. One of the most common patterns is the tenon cutter.

For precise movement of the cutter according to a given pattern, copy rings are used. The principle of operation is that the bushing creates support for the template, and the router copies it exactly during operation. When choosing the diameter of the copy sleeve, it is important to remember that it must be larger than the working diameter of the cutter. That is why craftsmen, when making templates, monitor the difference between their radii, and not their diameters. This is due to the fact that the router, while moving inside the template, will cut out a smaller pattern, and when working outside of it, the figures will be larger.

Having learned how to use a copying sleeve for a router, craftsmen receive a good assistant in processing various wooden parts.

Making templates

Many craftsmen use templates, especially when it comes to creating a series of wooden parts. It rarely happens that a template is used to cut out one part, but such cases do occur, for example, during restoration.

In most cases, such a device is used in production:

When making a template, it is important to initially select high-quality and durable material. Even taking into account the minimal contact of the machine router and the edge of the template, it is erased over time, and the drawings lose their original accuracy. Such problems can be easily avoided if you initially use durable materials:

- metal;

- textolite;

- multilayer plywood;

- some types of plastic.

Naturally, it will be difficult to prepare a metal template, but it will last for many years without deforming and maintaining the original dimensions and strokes of the design. It is better not to experiment with such a device and make a template specifically for the required part of the wooden product. There are no high-quality universal devices.

Attachments for woodworking

Processing wooden workpieces gives wide scope for using a router. Professional carpenters and carpenters use automatic machines that perform specified functions accurately and quickly, but manual machines are also good at what they do. Some, with the help of tenoning parts or attachments, can create real miracles. In some cases, it is even possible to carve the parts needed to assemble the furniture.

Processing wooden workpieces gives wide scope for using a router. Professional carpenters and carpenters use automatic machines that perform specified functions accurately and quickly, but manual machines are also good at what they do. Some, with the help of tenoning parts or attachments, can create real miracles. In some cases, it is even possible to carve the parts needed to assemble the furniture.

Each attachment is designed for a specific type of wood and can easily give the end part any shape. With their help, skirting boards, panels, cornices, balusters and much more are made. An experienced craftsman with one nozzle is able to perform various patterns on the surface of the workpiece using different angles. In addition, specialists often make such devices for a hand router with their own hands.

Special kits

In the woodworking industry, kits designed for special applications are often found. These include, for example, the production of inserts for hinges. This set is a customizable template that is immediately equipped with fasteners for milling.

Craftsmen make most of these parts themselves. It is enough to install a second stop jig on the rods and then a router will be securely attached to the end of the door leaf, which can easily be used to cut holes for hinges or a door lock. This method is useful, but inconvenient, so it is more suitable for one-time use.

Craftsmen make most of these parts themselves. It is enough to install a second stop jig on the rods and then a router will be securely attached to the end of the door leaf, which can easily be used to cut holes for hinges or a door lock. This method is useful, but inconvenient, so it is more suitable for one-time use.

Milling work is a great way to earn extra income by processing wooden blanks or just to while away your free time. These works require minimal investment, and most of the devices can be done with your own hands.

Products made from wood are distinguished by their uniqueness and environmental friendliness, which is why they are so valued. But you won’t be able to make a wooden masterpiece with your own hands without a hand router. In addition, it will need accessories with the help of which the craft takes on a given shape.

You can even make them with your own hands, and no special strength or skills are required. Before working with a router, you must first familiarize yourself with each of these devices, as well as learn how they work. In this article we will look at the most necessary designs for a router.

Device - rip fence

This device, as a rule, is already sold along with the router. Therefore, there is no need to develop and create it independently. For reliable support of the processed material, this element is used. With it, the movement of the cutter becomes rectilinear relative to the base surface, which can be a table guide, slats or straight edge part.

This device makes it possible to quickly mill various grooves and process edges while firmly holding the material.

Guide rail

If you need to make a straight cut with a router, then you cannot do without this device. To make it you will need any flat board, for example, you can use a piece of chipboard.

First you need to find out the distance from the edge of the milling base to the center of rotation, and it is always the same. To do this, you need to screw a guide to the unnecessary part of the material and make a test cut. Then you should measure the gap from the edge of the cut to the tire, to which the radius of the cutter is added. As a result, it will be possible to obtain the required value. For example, it is 59 mm, and the diameter of the groove cutter is 14 mm, that is , its radius is 7 mm.

Then you should draw a line for the cut, from which we retreat a distance of 52 mm (59-7), and draw another one. We fix the guide along it and make the cut.

Circle milling

Compasses are used for such purposes. With their help, the router can move around a circle. The simplest of them is a device consisting of a rod, one end of which is equipped with a screw with a pin, and the other is attached to the base of the tool. Of course, it is better to use a compass equipped with two rods.

In general, there are many proprietary and even homemade devices for a router for cutting circles, which differ from each other in ease of use and dimensions. Quite often, compasses have a mechanism changing the radius of the circle. As a rule, it is a screw with a pin at the end that moves along the groove of the router.

When it is necessary to mill a small circle, the pin should be located under the base of the tool. In these cases, other devices are also used, fixed at the bottom of the device base.

But you don’t have to buy a milling compass to cut out circles. Instead, you can use a rip fence. To do this, the device is attached to a groove on the sole. A screw is screwed into it, which is recommended to be equipped with a sleeve so that its diameter matches the size of the hole. That's it, the compass is done. The radius can be adjusted using the stop.

Devices for replication and copying

To create a series of identical products use:

To create a series of identical products use:

- Angle lever;

- Copy probes.

There is a scale on the angle lever, the division price of which is 1/10 mm. It allows you to center a stop ring under the cutter, which helps accurately reproduce the shape of the part on the workpiece during copying. It is often equipped with a chip guard and support plate for best edge finishing.

Using copy templates and rings

Copy rings are a round plate with a protruding edge that slides along the base surface along the template. This device provides an accurate path for the cutter to move. Basically, this element is installed on the base of the workbench. At the same time, there is Several methods for attaching it:

- Installation of special antennae in the holes on the sole;

- Screwing the ring into the threaded recess.

Using a template also allows you to achieve more efficient and accurate work. It is attached directly to the workpiece with double-sided tape, and then both parts of the device are pressed to the machine with clamps. Moreover, experienced milling operators advise checking how tightly the ring is pressed to the edge of the template.

In addition, with such a device you can not process the entire edge, but only the corners. Hence, procedure for processing material according to a template- an excellent option for cutting grooves for the product.

Dust removal devices

Professional craftsmen, in order to ensure dust removal, specially buy a technical vacuum cleaner, which is connected through an adapter with a hose to the router. Moreover, it does not interfere with operating the tool, and the markings and place of processing of the product are always open for visual inspection.

Professional craftsmen, in order to ensure dust removal, specially buy a technical vacuum cleaner, which is connected through an adapter with a hose to the router. Moreover, it does not interfere with operating the tool, and the markings and place of processing of the product are always open for visual inspection.

It is very difficult to work without a suction unit. But not everyone decides to make such a purchase, since it is too burdensome in terms of money and, moreover, is not always justified. True, there is another solution; you can get rid of dust with a household vacuum cleaner.

Install between the milling machine and the vacuum cleaner hermetically sealed tank. It will catch the bulk of the dust. It is equipped with an additional hose, and a fabric mesh is inserted inside. Moreover, these designs can be purchased ready-made or made with your own hands. By the way, a homemade device will help a household vacuum cleaner to collect even large construction debris and wood dust.

Slot milling device

This device is used for processing longitudinal grooves on posts, balusters and other rotating bodies. The principle of its operation is as follows. A baluster is installed into the body and fixed. Using a locking screw and a disk, the workpiece is secured in a strictly defined position.

After which the carriage is set in motion and the milling a groove along the length of the product. Then the part is unlocked, rotated to the required angle, locked, and the next groove is created.

Instructions for wood carving with a router

Beginning craftsmen may find working with hand tools difficult because the process of operating them seems difficult. That is why, before you start milling, you need to familiarize yourself with the principle of its operation.

Router assembly

The first step is to check the mounting location of the cutter in the machine; as a rule, a collet chuck is used for this. First, you need to select the desired cutter that matches the size of the chuck. If necessary, you can replace it.

But when deep processing is necessary, an option with an extended shank is used, which is inserted into the chuck hole and secured with a key. This must be done carefully without applying force, otherwise you will overcook, which is not the norm for the correct operation of the router. Although it is worth trying to reach a good stop so that the cutter does not wobble. All that remains is to tighten the spindle lock and you can get to work.

After this, the router turns on, you need to get used to the sound and feel the start. It is often because of surprise that many people start getting married.

Depth selection

In addition, you will need to install a milling depth limiter. First, the machine is applied to the product from the edge, while the cutter should not come into contact with the material. You will have to press on it until it reaches the required depth, after which position is fixed.

In addition, you will need to install a milling depth limiter. First, the machine is applied to the product from the edge, while the cutter should not come into contact with the material. You will have to press on it until it reaches the required depth, after which position is fixed.

For a more accurate value, use a phased limiter. You can find out its pitch in the manual for the router. In this case, the regulator is rotated by the required number of degrees.

First of all, the required speed is determined. This is done according to the table in the instructions, based on the diameter of the cutter and the material being processed.

If you have never worked with a router before, then it is better to try your hand at a rough version. In addition, this will help you set the necessary parameters directly in processing mode.

It is also advisable to compare the results after moving the tool clockwise and counterclockwise, toward you and away from you. When milling a product around, the correct direction is counterclockwise, and on the flat side, on the contrary, away from you. Then you can start carving the main workpiece.

Template for a manual router installed in a “table”.

More precisely, this is a homemade stop that can be used with a whole set of templates. The workpiece is installed into this stop along with the required template and clamped with cam eccentrics.

As we usually use a hand router when copying parts according to a template. The template is made from durable sheet material, such as MDF. The template is attached to the workpiece with self-tapping screws and the part is passed through with a router using a cutter with a support bearing, or a special copier ring, which is included in the standard set of accessories and is attached to the platform of the router itself.

Top to bottom, cam clamp, template, workpiece.

The device is assembled.

Such options have their advantages; you don’t need a table for a router. But with a large number of parts to be processed, it gets boring to twist the template every time. This method is convenient because the device you make can be used for a long time. And if you also make a set of the most popular templates for it, then time and labor costs will be significantly reduced. An unusual way of working.

The material for the base should be quite rigid; you can probably use plywood with a thickness of 10-12 mm. , but I think a 6-8 mm thick MDF board would be better. . The vertical wall and eccentrics are made of dense wood, oak, beech, or, in extreme cases, birch.

In fact, all parts except the base area can be made from 20 mm thick plywood. , but I think eccentrics made of plywood will be worse than those made of oak.

Holes are drilled on the vertical part for the bolt that secures the cams. The holes are made in vertical rows so that the eccentrics can be rearranged in height, depending on the thickness of the part and the template. The hole markings are in the figure. The thickness of the vertical oak part is 16-25 mm. .

When assembling, the parts are twisted with self-tapping screws, you can coat the joints with glue and the caps must be recessed. Here you need to keep in mind that during operation the base area may fall under the cutter, and sooner or later it will have to be changed. As for the vertical part, handles and eccentrics, they should last a long time. The cams are mounted on bolts with a diameter of 5 mm. . Instead of nuts, it is better to use wings so that they can be easily tightened by hand.

The handles hold the platform and the vertical part together; in addition, you use them to hold the device in use. Make such classic curly ones, or use a simpler option, it’s your choice.

In order to ensure the normal operation of the milling machine, it is necessary not only to handle the device used correctly, but also to correctly use, in other words, devices for So that this tool has the ability to form a workpiece in accordance with the requirements of the master (that is, cutting off the edges and other places of the material where it is needed, and not where “it happened so”). So, it is precisely to give the processed material a clear planned shape that the farm uses “devices” for a manual milling machine.

The difficulty of making homemade devices

Often, manufacturers themselves complete their products at the production stage; however, unfortunately, not every company will be able to please consumers with a complete set of all necessary tools. And why do this if at any time you can make a suitable tool with your own hands in a garage. This can be done even without a preliminary drawing: their design is so primitive that even a novice master can cope with such work. To make a parallel stop or any other part, it is enough to have a drawing of this device and a minimum set of tools. But if you want to make a homemade table for a hand router, you definitely can’t do without a drawing. You need to calculate everything correctly, designate the dimensions of the table, and then get to work.

How to work with a hand router?

Before carrying out milling work on wood, you need to make sure of the following:

- Is the cutter secured in the collet?

- Does the additional device installed on the workbench correspond to its power and speed?

- Is the required milling depth set (when working with submersible devices, this indicator is measured using a special immersion limiter).

- When working with it, make sure that a guide ring or bearing is installed that provides the desired trajectory of the device (the thickness of the cutter should be no more than three millimeters).

We pay attention to supports for parts when performing work.

When considering the question “how to work with a manual router,” it is also necessary to note that the part you are processing must always have some kind of support. For example, before the engine is turned on, the edge of the sole or bearing is pressed against a guide piece or template. Only then does the master turn on the machine and begin milling.

Below we will look at what types of tools there are for a router and what makes them special.

Rip fence

The rip fence is one of the few devices that is already included with every router. Therefore, there is simply no need for their independent development and production. As for the functions, with the help of the mentioned element it is possible to make a reliable stop for the material being processed, thereby ensuring the linear movement of the cutter relative to the base surface. The latter can act as a straight edge of a part, a guide rail or a table.

With this attachment for a hand router, you can quickly process edges and mill various grooves, holding the material almost in the “dead center” position.

Guide rail

This tool has similar functions to the previous one. Like the rip fence, the guide rail ensures extremely smooth, straight-line movement of the device. Working with a manual wood router using a guide rail can significantly reduce the time spent on processing a particular part. In addition, using the specified equipment, you can install the mechanism at almost any angle relative to the edge of the table.

In some cases, the design of the tools in question provides for the presence of special elements that facilitate the performance of certain operations (for example, this may be the function of cutting holes at the same distance opposite each other).

Copy rings and templates

Devices for a hand router, such as copying rings, are a round plate with a protruding shoulder that can slide along the surface along the template, thereby ensuring the exact trajectory of the cutter. Often this element is attached to the base of the workbench. There are several ways to install it:

- Screwing the ring into a threaded hole.

- Installation of special antennae of the device into the holes on the sole.

If you have such a device for a manual router as a template, you can also achieve more accurate and efficient work. The designated

the element directly on the workpiece itself, after which both parts of the device are pressed against the machine using clamps. Upon completion of the work, experts recommend checking the condition of the ring - see whether it is securely pressed against the edge of the template or not.

Another feature of the tool in question is the ability to process not the entire edge, but only its corners. At the same time, some devices for a hand router allow you to make curves of four different radii at once. Thus, the process of cutting material using a template is an excellent way to cut grooves for a part.

Compasses

These homemade devices for a manual router are designed to move the entire machine in a certain circle. The design of this tool includes a main part (a compass consisting of one rod), attached at the end to the base of the router, and a secondary part - a screw with a pin inserted into the hole of the machine. The value is set directly by the offset of the machine relative to the device design. Before starting work, you must carefully secure the tool to the base and make sure that the router is in good condition and is functioning normally. It is worth noting that the most effective and easiest to use is the compass that has not one, but two rods.

Most often, this instrument is made of transparent plexiglass. A small metric scale is additionally applied to its surface. It is worth noting that some models of compasses can have a circumference of up to 150 centimeters. Using this device, you can easily make a round tabletop for several people.

However, let's return to the principle of operation. Using an angular lever with a precise scale, copying is carried out on the workpiece. In this case, here you have the opportunity to center the ring directly under the cutter. The angle arm, which is complemented by a special support plate, also ensures precise edge milling.

The entire structure of this device consists of a base plate, a set of probes and a chip protection device.

Devices for copying identical devices and parts

This characteristic refers to a set of tools consisting of an angle lever and special copying probes, which are needed for the manufacture of a batch of identical parts. Most often, such equipment is used in cases where there is a need to replicate small-sized wooden devices. But before you start working with such a router, you need to prepare the angle lever scale in advance (division value is 1/10 mm).

Once the scale is set, you will be 100 percent sure of the correct centering of the thrust ring under the cutter, the location of which depends on the values set on the angle lever. Also, this adjusting element can be equipped with a support board and a special mechanism that protects the surface of the device from chips. The use of such parts will significantly speed up and secure the processing of product edges.