The large size of the corrugated sheeting, which allows one sheet to cover the area from the ridge to the eaves, makes it tempting to make the roof almost horizontally - this is the easiest way to install structures. It is better to abandon such an idea solely because the minimum slope of a roof made of corrugated sheets can result in damage to the roof in winter from snow loads, and in summer the penetration of water into the under-roof space under the influence of strong winds. On the other hand, the steeper the roof slope, the less snow will linger on it, and water has no chance at all of wetting the ceiling in the house. But such a roof is more difficult to build. How to find the golden mean, what angle of inclination to choose so that it is easier to build and the under-roof space is guaranteed to remain dry?

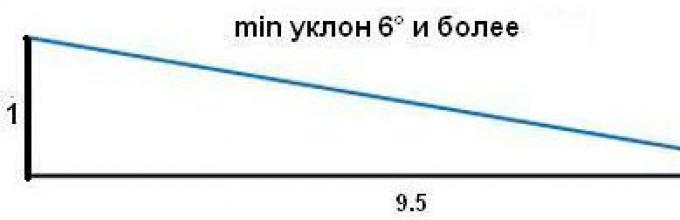

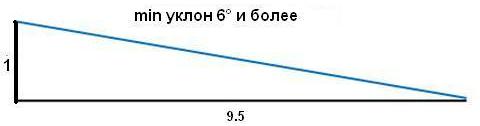

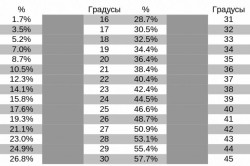

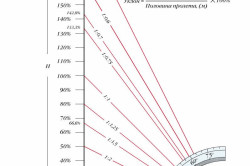

Angles in general, including the angle of inclination of the roof, are usually measured in degrees. But in SNiP it is customary to measure slopes as percentages, which are determined by the ratio of the height of the roof from the floor to the ridge to the distance from the projection of the ridge on the floor to the eaves, multiplied by 100. For example, 1: 9.5 x 100 = 10.5%. Therefore, to make it clear what angles we are talking about, we present a table of correspondences.

| Degrees | % | Degrees | % | Degrees | % |

|---|---|---|---|---|---|

| 1 | 1,7 | 16 | 28,7 | 31 | 60,0 |

| 2 | 3,5 | 17 | 30,5 | 32 | 62,4 |

| 3 | 5,2 | 18 | 32,5 | 33 | 64,9 |

| 4 | 7 | 19 | 34,4 | 34 | 67,4 |

| 5 | 8,7 | 20 | 36,4 | 35 | 70,0 |

| 6 | 10,5 | 21 | 38,4 | 36 | 72,6 |

| 7 | 12,3 | 22 | 40,4 | 37 | 75,4 |

| 8 | 14,1 | 23 | 42,4 | 38 | 78,9 |

| 9 | 15,8 | 24 | 44,5 | 39 | 80,9 |

| 10 | 17,6 | 25 | 46,6 | 40 | 83,9 |

| 11 | 19,3 | 26 | 48,7 | 41 | 86,0 |

| 12 | 21,1 | 27 | 50,9 | 42 | 90,0 |

| 13 | 23 | 28 | 53,1 | 43 | 93,0 |

| 14 | 24,9 | 29 | 55,4 | 44 | 96,5 |

| 15 | 26,8 | 30 | 57,7 | 45 | 100,0 |

When the roof slope is from 6° to 12°, it is necessary to seal the longitudinal and transverse joints between the sheets. For slopes greater than 12°, sealing joints is not necessary. It is enough to adhere to the recommended parameters for overlapping sheets in the longitudinal and transverse directions. But all this General requirements building codes and regulations.

When the roof slope is from 6° to 12°, it is necessary to seal the longitudinal and transverse joints between the sheets. For slopes greater than 12°, sealing joints is not necessary. It is enough to adhere to the recommended parameters for overlapping sheets in the longitudinal and transverse directions. But all this General requirements building codes and regulations. What else influences the choice of roof slope from corrugated sheets?

Here are the main points that determine not only the slope, but also much more:- Financial opportunities come first.

- The building plan determines the very shape of the roof.

- The presence or absence of an attic.

The desire to have an attic also results in significant costs both for its arrangement and for the design of the entire system of rafters and sheathing.

The desire to have an attic also results in significant costs both for its arrangement and for the design of the entire system of rafters and sheathing. Snow and wind loads, unfortunately, do not depend on the financial capabilities of the construction customer. Quite the contrary - they dictate their terms and force them to bear certain costs to ensure the strength and safety of the roof in general and the roof in particular.

It is always desirable to slope the roof so that the snow does not linger on it, but rolls down almost immediately when it snows. Unfortunately, this is not always possible and not in all regions. In some conditions, spontaneous snow melting is generally not desirable for safety reasons. In such cases, snow-retaining structures are installed on the roof, and the snow is thrown down, subject to the necessary organizational and technical conditions. The design of the rafters and the rigidity of the corrugated board are of particular importance here.

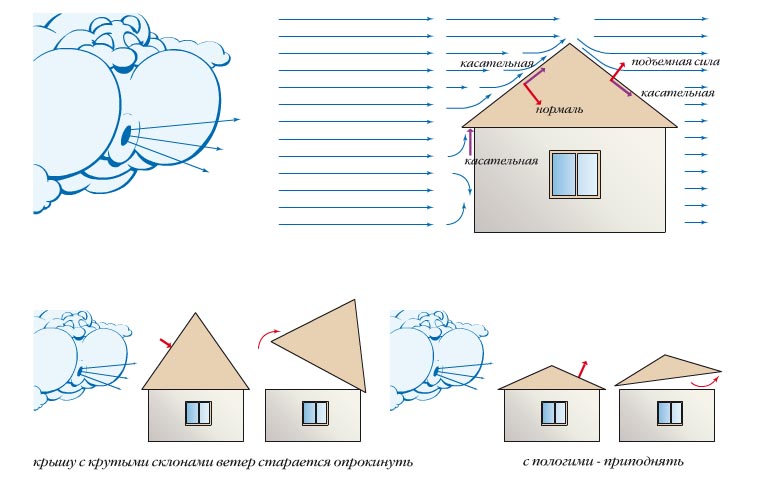

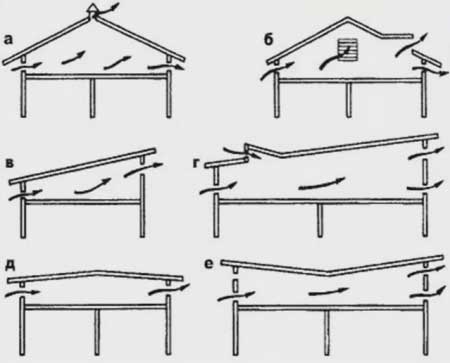

It is always desirable to slope the roof so that the snow does not linger on it, but rolls down almost immediately when it snows. Unfortunately, this is not always possible and not in all regions. In some conditions, spontaneous snow melting is generally not desirable for safety reasons. In such cases, snow-retaining structures are installed on the roof, and the snow is thrown down, subject to the necessary organizational and technical conditions. The design of the rafters and the rigidity of the corrugated board are of particular importance here.  IN last years Hurricane winds occur even in places where previously they were only heard about on the radio and seen on TV. Therefore, it is especially necessary to pay attention to wind loads during new construction and when repairing old roofs. It is not always possible to reduce the windage of a roof, so a slope that allows you to reduce the lifting force will partially help solve the safety problem. It is also necessary to take measures to eliminate the possibility of gusts of wind blowing under the sheets and subsequently tearing them off. All the necessary design solutions for this are available. You just need to strictly follow them when carrying out construction and installation work. With the help of snow and wind load maps, you can decide on the choice of the profile height of the corrugated sheet and the angle of the roof. The profile height directly affects the rigidity of the profiled sheet, and therefore its bearing capacity. A more rigid corrugated sheet can withstand a greater snow load, which means the roof can be made flatter. On the other hand, the smaller the angle of inclination of the roof, the greater the chance that in strong winds it may not be protected from moisture penetration into the roofing “pie” through the joints of the corrugated sheeting. And a flatter roof requires stronger support in the form of a complicated rafter structure.

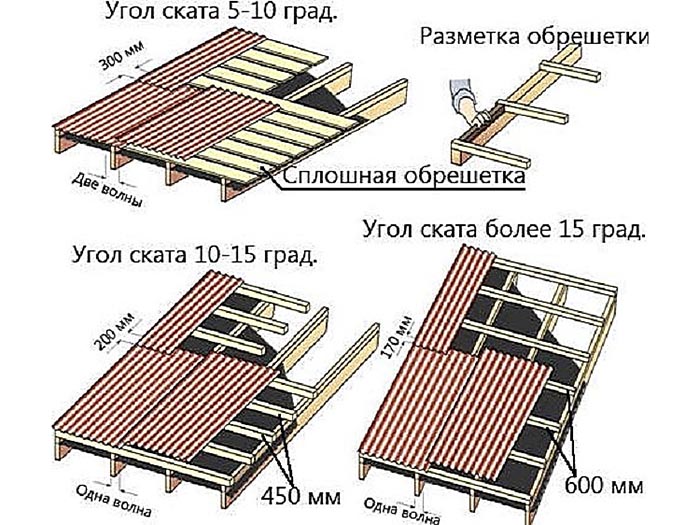

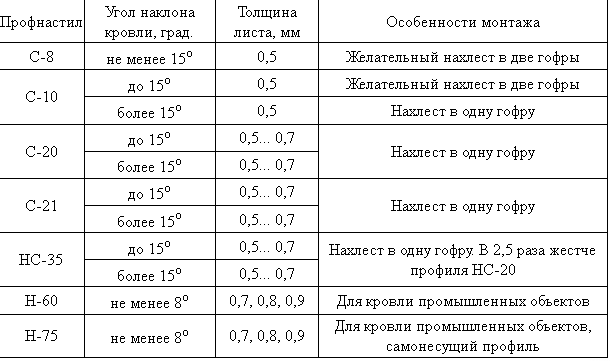

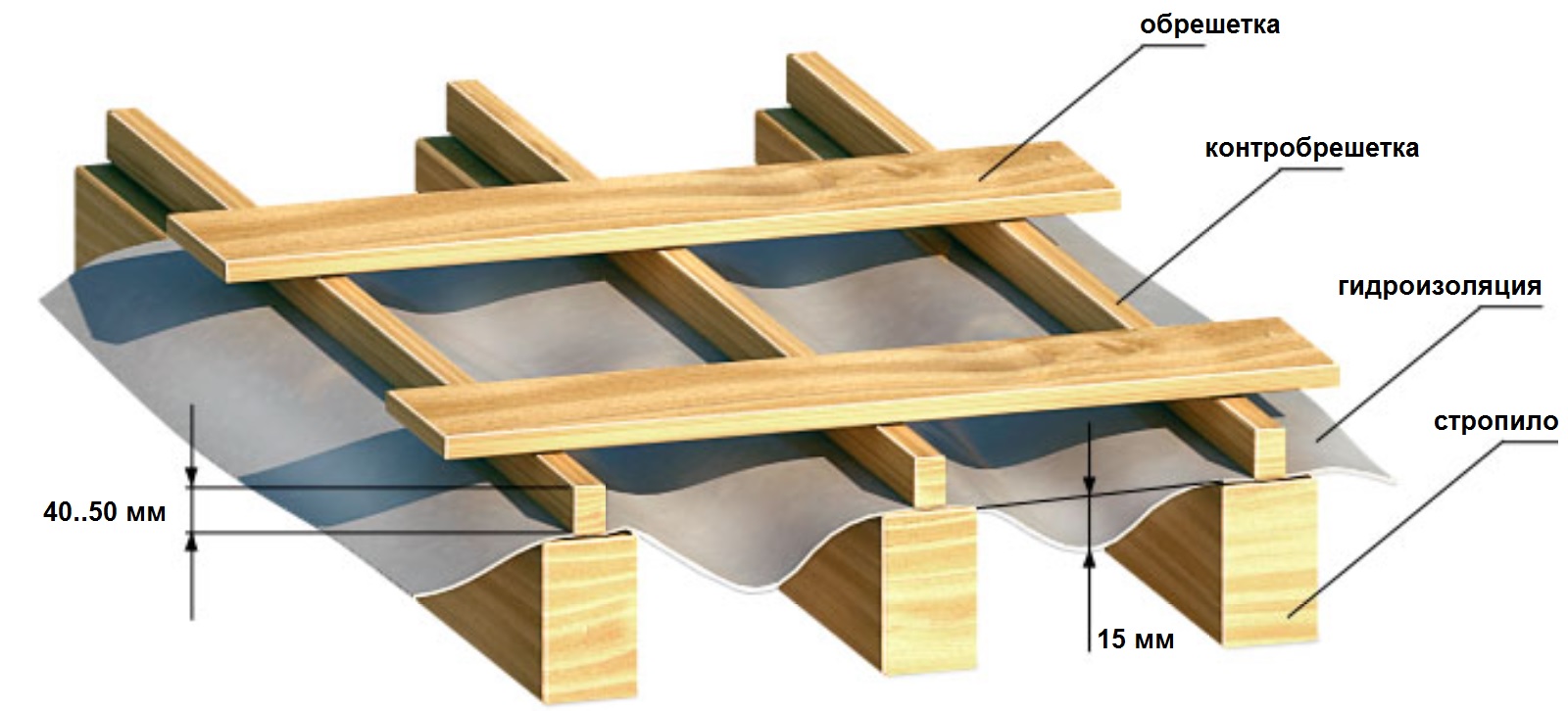

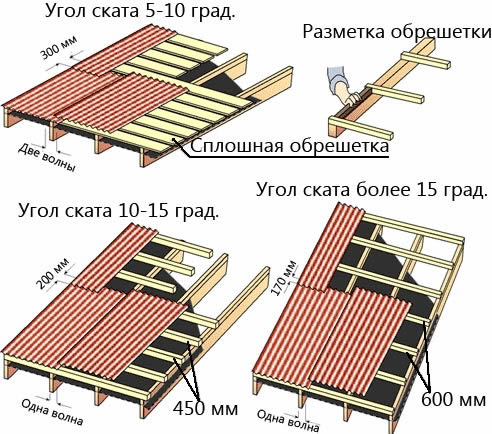

IN last years Hurricane winds occur even in places where previously they were only heard about on the radio and seen on TV. Therefore, it is especially necessary to pay attention to wind loads during new construction and when repairing old roofs. It is not always possible to reduce the windage of a roof, so a slope that allows you to reduce the lifting force will partially help solve the safety problem. It is also necessary to take measures to eliminate the possibility of gusts of wind blowing under the sheets and subsequently tearing them off. All the necessary design solutions for this are available. You just need to strictly follow them when carrying out construction and installation work. With the help of snow and wind load maps, you can decide on the choice of the profile height of the corrugated sheet and the angle of the roof. The profile height directly affects the rigidity of the profiled sheet, and therefore its bearing capacity. A more rigid corrugated sheet can withstand a greater snow load, which means the roof can be made flatter. On the other hand, the smaller the angle of inclination of the roof, the greater the chance that in strong winds it may not be protected from moisture penetration into the roofing “pie” through the joints of the corrugated sheeting. And a flatter roof requires stronger support in the form of a complicated rafter structure.  There is also a relationship between the slope angle, the section of the flooring profile and the roof sheathing. If the angle of inclination of the roof is less than 10°, it is recommended to make the sheathing continuous, the transverse overlap of the corrugated sheets should be at least 300 mm, and in the longitudinal direction it is better to lay two waves of the next sheet on top of the previous sheet. With a slope of 10° to 15° in the longitudinal direction, you can limit yourself to one wave, and for a transverse overlap, 200 mm is enough. The sheathing pitch can reach 450 mm. When the angle of inclination exceeds 15°, the sheathing pitch can be increased and the overlap reduced.

There is also a relationship between the slope angle, the section of the flooring profile and the roof sheathing. If the angle of inclination of the roof is less than 10°, it is recommended to make the sheathing continuous, the transverse overlap of the corrugated sheets should be at least 300 mm, and in the longitudinal direction it is better to lay two waves of the next sheet on top of the previous sheet. With a slope of 10° to 15° in the longitudinal direction, you can limit yourself to one wave, and for a transverse overlap, 200 mm is enough. The sheathing pitch can reach 450 mm. When the angle of inclination exceeds 15°, the sheathing pitch can be increased and the overlap reduced.  Of course, the pitch of the sheathing also depends on the height of the profile. The more rigid the profiled sheet is, the larger the pitch can be. The latter can also be changed depending on the cross-section of the board or timber used.

Of course, the pitch of the sheathing also depends on the height of the profile. The more rigid the profiled sheet is, the larger the pitch can be. The latter can also be changed depending on the cross-section of the board or timber used. Sheathing sections depending on the roof slope and rafter pitch, mm |

||||||

| Lathing pitch, mm | Roof slope |

|||||

1:3 and flatter |

||||||

| Rafter pitch 0.9 m | Rafter spacing 1.2 m | Rafter pitch 0.9 m | Rafter spacing 1.2 m | Rafter pitch 0.9 m | Rafter spacing 1.2 m | |

| 250 | 22x100 | 25x100 | 22x100 | 25x100 | 22x100 | 32x100 |

| 300 | 22x100 | 25x100 | 22x100 | 32x100 | 25x100 | 32x100 |

| 400 | 22x100 | 32x100 | 22x100 | 32x100 | 25x100 | 38x100 |

| 450 | 22x100 | 32x100 | 25x100 | 32x100 | 32x100 | 38x100 |

| 600 | 25x100 | 32x100 | 25x100 | 32x100 | 32x100 | 38x100 |

| 750 | 32x100 | 38x100 | 32x100 | 38x100 | 32x100 | 50x100 |

| 900 | 32x100 | 38x100 | 32x100 | 38x100 | 38x100 | 50x100 |

| 1200 | 32x100 | 50x100 | 32x100 | 50x100 | 38x100 | 50x100 |

| 1500 | 50x100 | 50x100 | 50x100 | 50x100 | 50x100 | 50x100 |

Selecting a slope option

Ultimately, the right to determine the slope of a corrugated sheet roof remains with the customer. After all, it is obvious that such a number of factors influencing the strength characteristics of the roof imposes certain restrictions. But at the same time, they presuppose freedom of choice. For example, with all the “aggravating” loads on the roof, you can use a corrugated sheet with greater rigidity than what is expected in the calculations, or reduce the pitch of the rafters and increase the cross-section of the timber for the sheathing. This will reduce the angle of the roof. When performing installation, in any case, it is necessary to follow all the recommendations of building codes and regulations, as well as practitioners, and then even the most minimal slope of a corrugated roofing will not cause problems during operation and will not become a reason for disappointment.At the moment, corrugated sheeting is the most popular building material, with the help of which it is easy to build both standard and original structures. Pediment, fence, roof, building facade behind a short time will be transformed.

The time has passed when a pitched roof was considered the best option for bathhouses, sheds, and cabins. Now it is interesting to use this form in a non-standard project. An atypical roof looks organic against the backdrop of many landscape design trends.

- Despite the windage of the corrugated sheet, the pitched roof correct location It is considered safe even with large gusts of wind. In this case, special attention is paid to waterproofing.

- A roof of a simple configuration can be erected quite quickly.

Each sheet of cold-rolled steel is factory-coated with multiple layers. Due to the passage through the forming shaft of roll forming machines, the surface becomes ribbed (corrugated) and rigid. The higher the rib height, the stronger the building material. Corrugated sheeting is perfect for creating pitched roof.

Shed roof made of corrugated sheets

What is good about corrugated sheeting for a pitched roof?

The building material has:

- durability;

- financial accessibility;

- color variety;

- variability of shapes and sizes;

- ease of installation and transportation.

Important! If the roofing “pie” is installed incorrectly, heavy rain, hail, and snow can be heard inside.When the protective polymer layers of corrugated sheeting are damaged in certain places, the exposed areas are covered with special paint.

From project to implementation

How to determine the slope angle of a pitched roof

Among the important parameters characterizing the roof, experts call the angle of inclination of the slopes relative to the horizontal surface - slope.

This parameter influences a number of important operational and structural features of the roof.

It is logical that the angle of inclination of a pitched roof is not chosen arbitrarily, but depending on climatic conditions, the prevailing wind rose in the area, the amount of precipitation, the structural type of the rafter system, roofing and the length of the slopes.

Let's consider the roofing material - profiled steel sheet (corrugated sheet) and the minimum slope of the roof made of corrugated sheets, recommended building codes and rules (SNIP).

If there is no overflow of water between the corrugations, the angle of inclination is considered minimal. IN otherwise the formation of puddles is inevitable.

Angle of inclination of a pitched roof made of corrugated sheets

The choice of pitched roof angle depends on:

- from the height of the walls of the building;

- climatic features of the region of the country (how much snow falls, how often there are gusts of strong wind);

- type of selected corrugated sheet.

Remember!The flatter and lower the slope of the roof, the thicker the waterproofing material should be, and the more the joints are sealed. Roofing activities are simple and can be done independently if you follow the ready-made instructions.

How to calculate loads

First of all, the region of operation is taken into account. Corrugated sheeting as a roofing material has a special windage, so the roof should not be made too steep.

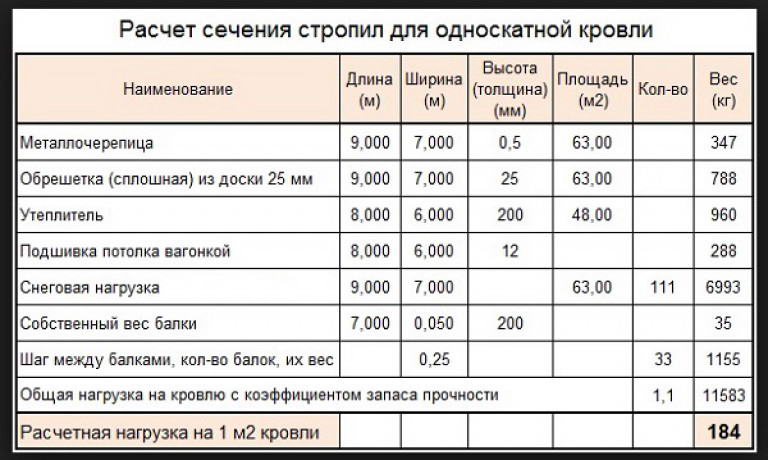

A layer of snow more than a meter thick will bend the profiled sheets on the roof of the building. This means that calculations must be approached with full responsibility.

In addition to taking into account wind loads, humidity, temperature changes, and other precipitation are taken into account.

Calculation of the cross-section of rafters for a pitched roof

How to design ventilation

With a minimum slope, a combined pitched roof without an attic is built. External air flows pass through the channel in the top panel and through the air gap in the roofing “pie”. This mechanism prevents the formation of condensation.

Another condition for a well-made pitched roof will be the thermal insulation of the house.

Important: protect the under-roof area from heat in the summer. A waterproofing film with a special coating on one side will perfectly reflect the ultraviolet rays of the sun

When an attic is not provided, the floor and roof are combined. This results in a common functional ventilation opening.

Installation of roof vents

Step-by-step example of building a pitched roof

Elements of a pitched roof

Step 1. Making a Mauerlat

To level all the tops of the sides of the house, the presence of a Mauerlat is mandatory.

- When a log house is erected, the upper crown plays the role of a mauerlat.

- If the walls are brick, creating a mauerlat is variable:

- a timber frame of the appropriate size is knocked down;

- a reinforced belt is created with steel studs, onto which a timber frame is placed. In this case, we achieve maximum horizontality, which allows us to evenly distribute the load on the walls. The angle of inclination of a pitched roof will be the same on both sides.

Step 2. Mark the rafters and make the sheathing

With a small margin, a board is laid on the Mauerlat. The upper and lower cuts are marked, which coincide in width with the Mauerlat. Based on the results obtained, the remaining rafters are marked.

The basis for a profiled pitched roof is board sheathing and steel purlins. The sheathing is made from the bottom up, each of the bars is attached to the rafter system with a bracket or a nail.

Then, roofing material is placed under specially mounted fillets, which prevents the penetration of dampness. The resulting overhangs are sheathed with siding. The created design looks neat and fresh.

Important! The higher the roof slope, the wider the sheathing pitch.

Sheathing of a pitched roof

Step 3. Install waterproofing

- When a pitched roof is poorly ventilated, an antioxidant film is used as a building material.

- The under-roofing film is lined from bottom to top with canvas with a certain margin.

- The water vapor barrier film is attached to the rafter mechanism using a construction stapler.

It is important to know: a vapor-permeable membrane will remove excess water vapor outside. This is important because it prevents the formation of an environment in which fungal colonies actively develop

Laying waterproofing for a pitched roof made of corrugated sheets

Step 4. Raise the corrugated sheeting to the roof

- we take a rope four times longer than the ladder, which is fixed on both sides from the bottom of the sheet;

- the arsenal should have a ladder resting on the ground, the length of the slope;

- the corrugation is laid from the bottom corner in a horizontal position;

- You cannot cut a steel sheet with a metal cutting machine, otherwise corrosion will appear at the cut site over time.

Step 5. Install the corrugated sheet

The corrugated sheeting on the “one-pitch” is fixed with a vertical strip. Docking is carried out at a single wavelength width. With an overlap of more than fifteen centimeters, corrugation is laid at the joint and near the wall. Self-tapping screws with a special rubber seal should only fit into the cavity.

The top sheets always overlap. For horizontal overlaps, a sealing gasket is used. We begin the final fixation when the evenness of the entire roof has been checked. Fastening the profiled sheet must be technologically advanced.

The end and ridge strip are mounted at the end. The first one does not compact; small gaps help natural air circulation.

Installation of corrugated sheeting on a pitched roof

Construction of complex structures

The roof structure of a complex configuration has a number of distinctive features. To prevent dust and moisture from entering the under-roof space, the joints are carefully sealed. Additional roofing elements are attached differently.

A continuous sheathing is made before fixing the valley strips. The lower fragment is secured along the edge with a nail or self-tapping screw. The upper fragment of the plank is bent in the joining area to the roof ridge. A sealant must be placed between the corrugation and the strip, or a sealing compound must be applied. The final fastening of the strip is carried out together with the fixation of the metal profile.

The upper fragment of the valleys carries a decorative load. It is also attached to the seal, sealing.

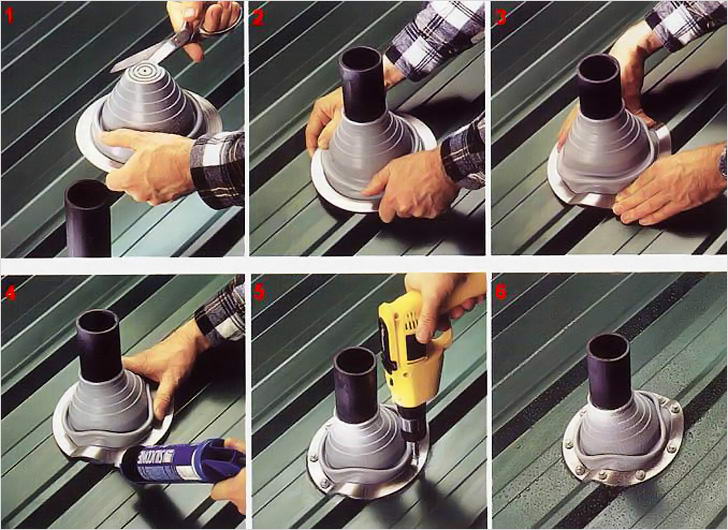

Chimney system in a complex roof

How to remove the pipe through the roof from corrugated sheets, see.

Option 1

How to bring a pipe through the roof

Option 2

How to remove a pipe through the roof from corrugated steel

How to build a multi-level roof under corrugated sheeting

The multi-level roof looks quite fresh and unconventional. A designer exterior is relevant when creating a private home. For example, a hip roof with an offset center will attract attention from afar. Combined roofs are colorful and elegant.

Remember! It is quite difficult to make a broken structure with a large number of connecting elements yourself, so it would not be a bad idea to involve experienced specialists.

- The main reasons influencing the choice of slope angle

- Calculation of the angle of inclination

- Calculation of roof under snow load

- Calculation of wind loads

- Basic requirements for installing corrugated sheet roofs

Minimum slope roofing from corrugated sheets, just like the maximum one, is selected not only from design conditions and appearance buildings. When choosing the slope angle on roofs, you need to take into account many different factors: from weather conditions to the size of the site and the opinions of neighbors. Choosing the desired option, taking into account all the parameters and appearance of the building, is quite difficult.

When installing a roof, one of the most important parameters included in the calculations is its slope. It depends on the material used and climatic conditions.

To make optimal use of the attic space of a residential building in the form of an attic room, you can install a sloping roof with two slope angles. The upper part has a slight slope, the lower parts depend on the size of the structure.

The main reasons influencing the choice of slope angle

The main conditions influencing the choice of roof slope from corrugated sheets:

- wind speed and prevailing direction;

- average precipitation in the form of rain;

- average snowfall depth.

A roof with a slight slope has a slight windage and, in the presence of cornices, gables and other elements, is almost not exposed to the wind. Orientation according to the wind rose in this option is not necessary. In regions with frequent heavy rains and thunderstorms, special attention should be paid to the reliability of the joints when installing the roof. A large number of With a slight slope, water will not have time to drain from the roof; some of the moisture may penetrate under the roof if the joints are not sealed.

In areas with long winters and heavy snowfall, large layers of snow can accumulate on roofs. A small slope will not allow the layer to move under its own weight. Loads on the structure will increase several times, especially during thaws and early spring. If the strength is insufficient, the roof structure may not withstand the loads and become deformed. The entire structure may collapse. Such roofs need to be cleaned periodically throughout the winter.

To ensure the reliability of roofs with minimal inclination it is necessary to strengthen the entire structure, use additional elements rigidity for the rafter system. When choosing a profiled sheet, you need to take into account its configuration. Sheets with a high wave have greater rigidity than the wall and universal profiles. The best option you need to choose based on the cost of roofing material and lumber.

Return to contents

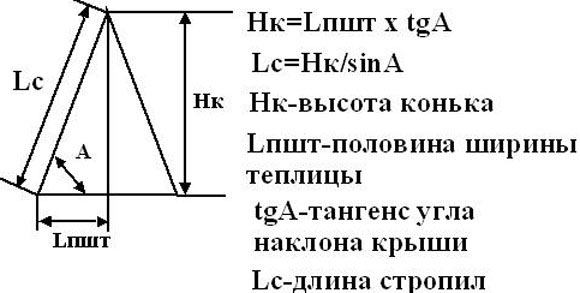

Calculation of the angle of inclination

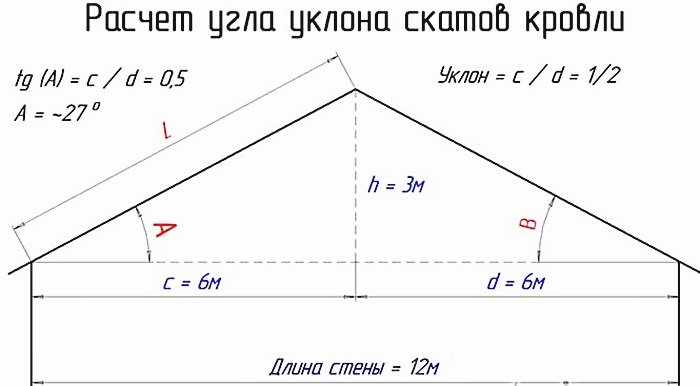

As an example, you can use a gable roof with a ridge located exactly in the middle of the building. Initial data:

- wall length – 12 m;

- roof height – 3 m.

Since the roof ridge is located in the center of the building, the roof shape will consist of two right triangles having a common leg - the height of the roof. The second legs will be equal to half the length of the wall. From the available dimensions, you can determine the tangent of the angle between any of the slopes and the horizontal surface:

- 3: 6 = 0,5.

Using the Bradis table or a calculator, you can determine the angle:

- 0.5 = tg 27°

The angle of inclination of each slope will be 27°. Using another function, you can determine the length of the ramp without taking into account the release. Quite often, for calculations, not the angle of inclination in degrees is used, but relative units or the percentage ratio between the length of the horizontal projection of the slope and the height of the roof. IN in this example the relative value will be ½ or 0.5. The relative value is expressed as a fraction, which is not always convenient and understandable when making calculations. For a more visual representation, a percentage is used. To determine the percentage, you need to multiply the relative value by 100%:

- 0.5 x 100 = 50%.

It should be understood that for a roof with a slope of 45°, the percentage will be equal to 100%, since the height of the roof and the projection length will be equal.

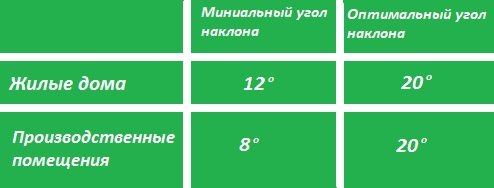

Based on the slope of the roof, it can be divided into the following types:

- flat, tilt angle up to 8°;

- with a slight slope from 8° to 12°;

- optimal from 12° to 30°;

- steep more than 30°.

For the manufacture of flat roofs they are usually used concrete plates And soft roof. Mainly used in the construction of large industrial buildings, warehouse premises. Roofs with a low slope are used in the construction of industrial facilities and private households. May have different configurations. Shed roofs are used in the construction of garages, sheds, sheds for various purposes, and small warehouses. Gable roofs often used in the construction of baths, summer kitchens, gazebos, living quarters.

The most widely used roofs are optimal angle tilts. They are used in the construction of buildings for various purposes. The configuration can be anything. Steep roofs are most often used on residential and administrative buildings. In addition to the main purpose, they perform decorative functions. The most popular material for constructing all types of roofs is profiled sheeting.

Return to contents

Calculation of roof under snow load

Snow loads are especially relevant for roofs with a slight slope. The amount of snowfall varies greatly throughout our country. Based on long-term observations and measurements, the territory is divided into 8 main zones that reflect the level of load on a flat surface.

To calculate the roof load you need to use the formula:

- Рсн = Рсн.т * µ;

- where: Рсн.т – snow pressure for a horizontal surface;

- µ – correction factor depending on the angle of inclination α.

If the angle of inclination of the slope is no more than 25°, µ = 1, from 25° to 60° - µ = 0.7, with a greater inclination the load is not taken into account, the snow will not be able to hold on. Example: The building is located in the fourth zone with a load of 240/168 kg/m 2. The planned roof angle is 35°.

At the first limit the value will be:

- 240 x 0.7 = 168 kg/m2.

For the second:

- 168 x 0.7 = 117.6 kg/m2.

Today, corrugated sheets are the most common building material. It is often used not only to create roofing, but also fences and facades. Using metal profiles, you can make light and at the same time strong floors, cover walls and ceilings, etc. In the case of using the material to cover the roof, the main role is played not by the slope of the roof made of corrugated sheets, but by compliance with installation recommendations. In any instructions for the material you can find confirmation that the key to the quality of work is a strong and reliable foundation - the lathing (more details: " "). Let's look at the main points of creating the base and figure out how the sheathing affects the slope of the corrugated roof.

In order to use a metal profile as a roofing material, it is necessary to comply with all SNiP standards ( sanitary standards and rules). According to the regulations, to create a roof you can use universal, wall or roofing types of metal profiles with a wave height of at least 20 mm.

In addition, it is recommended to use corrugated sheeting protected by a polymer coating that corresponds to the climatic conditions of the region. According to written requirements, you should choose the type of rafters and their spacing. Let's consider the factors that affect the slope of a pitched roof made of corrugated sheets (in more detail: "").

Parameters affecting roof slope

The slope of a corrugated roofing is influenced by many factors that must be taken into account when choosing the pitch of the sheathing and rafters, the material used and the conditions for its fastening. The minimum slope of a corrugated sheet roof should be selected in cases where large wind loads are observed in the region. Due to the windage effect, a high roof can be damaged or even destroyed.

It should be understood that even the most durable corrugated sheeting will not be able to withstand static or dynamic loads if the reliability of the base is in doubt. In order for the structure to be strong, it is necessary to strengthen the rafters with additional stiffeners. Reducing the spacing of the rafters and sheathing may also be a good solution.

In regions where heavy snowfalls are observed, the slope of a corrugated sheet roof should be much greater under other conditions. Sometimes the slope value is 45 degrees. This makes it easy to get rid of snow masses, preventing them from accumulating in a volume critical for the roof. In this case, there is no need to strengthen the rafters, since such a slope practically eliminates the load from snow.

In regions with little rainfall and a lot of sunny days, it can be done with a low slope and additional strengthening of the rafters. In this case, the roofing cake must contain an additional layer of thermal insulation, which will reduce heating interior spaces. In addition, it is recommended to use membrane waterproofing materials, which protect the roof from leaks, and attic space from condensate accumulation.

Technology of laying corrugated sheets on the roof

The thickness of the thermal insulation layer is determined based on climatic conditions. Steam and waterproofing must be included in the roofing pie, as they help protect the under-roof space from moisture penetration. In addition, there must be a ventilation gap between the corrugated sheeting and the rafters, which is designed to ensure proper operation of the rafters and reduce heat loss.

The sheathing pitch can range from 60 to 100 cm. In cases where it is necessary to strengthen the structure, the sheathing pitch can be reduced to 40 cm. This allows you to increase the roof's resistance to loads. The corrugated sheeting is placed directly on the sheathing, and it is secured with special roofing screws. The fastening pitch is selected in accordance with the pitch of the sheathing. The screws must be screwed into the lower point of the wave, strictly perpendicular to the rafters.

The overlap of corrugated sheets on each other can be 10-20 cm. The sheets are fastened with steel rivets or short roofing screws. If it has a small slope, it is better to use the two-wave overlap method.

How to measure the slope of a roof?

When installing a roof with a slope of less than 10 degrees, it is imperative to use membrane roof coverings that will protect the surface from leaks, taking into account. It is also important to remember that the smaller the angle of inclination, the larger the gap for ventilation should be.

Another piece of advice that is worth listening to when laying a roof with minimal angles stingrays The overlap of corrugated sheets must strictly correspond to the dimensions stated in the instructions. Sometimes, amateur builders neglect the requirements, believing that the specified overlap is too large, taking into account, and such a roof becomes more expensive. In this case, by reducing the size of the overlap, the home owner is condemning himself to additional roof repair work in the future. Since a small overlap will be unable to protect against heavy rain, moisture will enter the under-roof space.

A person who is poorly versed in the intricacies of construction may decide that architects choose the slope angle of a corrugated sheet roof only for aesthetic reasons. In fact, the slope of a corrugated roof is one of the most important characteristics. When choosing it, you should definitely take into account many initial parameters.

What influences the choice of roof angle

One of the important aspects that determines the angle of inclination is the climate in the region where the building will be built. First of all this:

- Height of snow mass;

- Precipitation amount;

- Rose of Wind;

- Roofing material;

- Strength of the rafter system.

It should be remembered that water will quickly drain from the roof, and snow will remain on it longer. You can imagine how much weight the roof must withstand, given that the level of snow drift in some regions can exceed 1 m. The more the corrugated sheet is inclined, the faster the snow mass will fall off it.

When choosing the slope angle of corrugated sheeting, you should take into account the parameters of the materials used that you have chosen for the roof. Example: a load-bearing profiled sheet with a high wave can be used even on the flat roofs of a shopping center. Wall or universal metal profile, suitable only for roofs with a large angle of inclination.

Important! If the roof slope does not exceed 12°, the horizontal seams should be treated with sealant to prevent water from getting under the joints.

Calculating the angle of inclination of a roof made of corrugated sheets

When calculating the slope of a metal profile roof, be sure to take into account the following parameters:

- The weight of thermal insulation material, lathing system, counter battens and other layers of roofing materials.

- The weight of the corrugated sheet itself.

- Snow load in your region.

- Loading due to gusts of wind.

Calculations according to the schematic drawing

Let's take the classic gable roof type as an example. As can be seen in the figure, A equal to the angle of inclination of the left slope, IN- right. Then, to carry out the calculation, you need to find out the height of the roof equal to h and the length of the horizontal section of the slopes With And d.

If the roof is symmetrical, With And d will be equal and to subtract them you will need to divide the walls 50*50.

Example: According to the schematic drawing, the sides of the roof are symmetrical, which means the corners A And IN- the same. Let's try to calculate the angles according to the existing example.