In any building, the main elements on which the maximum load falls are the foundation, walls and roof. The quality of the installation of the roof largely depends on whether it is correct or not, the device is made truss system. If the attachment points of the truss system do not meet certain requirements, then such a roof will not last even a minimum operational period without repair work.

Requirements for the truss system

The truss system of any roof must meet such important requirements as:

- Maximum rigidity. Any frame node must withstand loads without being deformed or displaced. The triangle obtained during the arrangement of the truss system must ensure the rigidity of the structure and its maximum stability;

- Optimal weight. Depending on the roofing material choose the material used for the rafters. Usually a wooden beam is chosen, but metal can also be used for heavy roofs.

Important! To prevent damage to the rafters, their rotting and the formation of fungus on wood, it is treated with an antiseptic, and metal structures with anti-corrosion compounds.

- The high quality of the materials used. The wood used as rafter legs should not have cracks and chips.

Varieties of truss systems

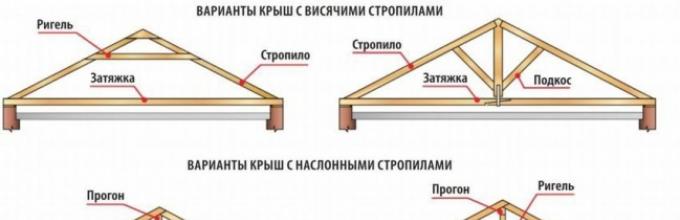

The roof can be equipped with one of the types of truss system, of which there are only two:

- Hanging rafters;

- Overhead rafters.

Hanging truss system

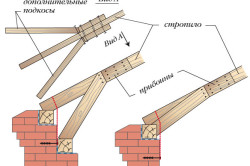

Such a system is optimal in the case of a gable roof, when the span between the walls is no more than 6 meters, but when installed additional elements also applicable to wider openings. The Mauerlat serves as the lower basis for the support, while the upper part of the structure abuts against each other. This design also contains a puff - necessary to relieve the load from the walls, by reducing the expansion of the rafters. Beam puffs are installed below the rafter legs and can serve as floor beams.

Attention! The role of tightening can optionally be performed by a wooden beam, it can also be an overlap made of reinforced concrete structures, which in some houses is equipped with an upper floor.

If the puff is located above the bottom of the truss system, then it is called crossbar. TO important points arrangement of a truss system of this type include:

- The roof overhang should not be allowed to rest on the lower part of the rafter legs, which extend beyond the wall. In such a situation, it is best to use a filly (the width of the overhang is set within one meter). With this arrangement, the rafter will be based on the Mauerlat. The cross section of the beam for the filly is chosen smaller than for the rafters;

- To give the roof additional rigidity, and prevent it from staggering and being destroyed by strong gusts of wind, a wind board is nailed on the slope, to the Mauerlat from the ridge;

- If the moisture content of the material used to equip the truss system is more than 18%, unsteadiness should be foreseen, which will cause gradual drying of the wood. That is why fastening should be done with bolts or screws, not nails.

Layered truss system

This arrangement is applicable for roofs with distances between walls from 10 meters (maximum 16 meters). The slope can be made at any angle, and inside the building there are load-bearing walls or supporting columns. From above, for the rafters, the ridge run serves as the main support, and from below this function is performed by the Mauerlat. The inner purlin is supported either by the inner wall or by the studs. Due to the presence of only vertical type of loads, there is no need to install the tightening.

With a 16-meter span, the replacement of the ridge run is carried out by two side structures, the support for which will be the racks.

Important! The absence of bends in the rafter legs is ensured by such nodes as struts and crossbars.

Particular attention to the arrangement of the roof using a layered truss system should be paid to such nuances:

Features of calculations of the truss system gable roof shown in the video:

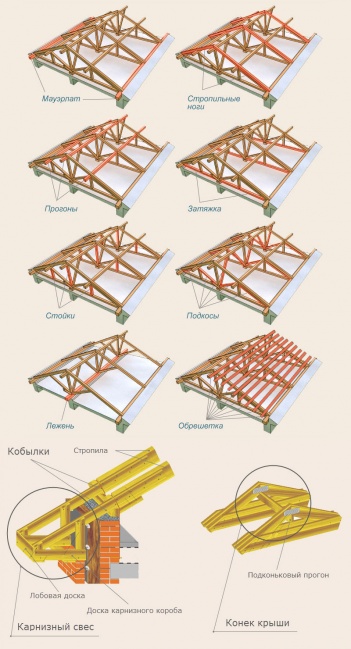

The main nodes of the truss systems

The main nodes of the roof truss system include:

- Rafter. They perform the function of a skeleton, supporting the internal and external elements of the roof, and also serve as the basis for laying communications;

- Mauerlat. This is a kind of roofing foundation, which is a beam on which the entire structure is installed. It performs an important function - uniform distribution of the load of the entire structure;

- Run. Designed for fastening rafter legs together and can be located both on top and on the side;

- Puff. Serves for fixing the rafters in the lower part of the structure;

- Struts and racks. Provide the most stable location of the rafter beams;

- Skate. The junction of the roof slopes;

- Filly. These are continuations of the rafter legs, which are sometimes equipped;

- Rigel. It is necessary for high-quality and reliable support of load-bearing elements;

- Sill. Cross bar necessary to distribute the load.

In addition to the listed elements, the design includes attachment points for the roof truss system. When performing them, it is necessary to follow certain rules.

Important! It is absolutely not worth performing a simple fastening of the base to the crossbar, as this can lead to the complete destruction of the truss system.

The following types of fasteners should be used:

- With emphasis on the end of the crossbar;

- Teeth point-blank;

- Teeth in a spike.

The number of teeth should be chosen depending on the slope of the slope, and additional structural reliability can be created using metal corners.

To the main attachment points roof structure relate:

- Beam knot;

- Mauerlat knot;

- Skate knot.

beam knot

With such a node for connecting elements, an insertion of teeth into a spike is made into the rafter, and a recess corresponding to the teeth is made in the transverse section of the crossbar. Such a recess or nest should not exceed 30% of the timber thickness. Fastening is carried out with special hardware with metal corners, or wooden beams, spikes and overlays.

Attention! If the roof is made of materials with low weight, and the slope of its slope does not exceed 35º, then the bases of the supports should be placed so that they rest against an area larger than the beam itself.

Mauerlat knot

Such fastening can be performed both by rigid technology and by sliding technology. Rigid technology involves the installation of a strong connection between the Mauerlat and the rafters, preventing the possibility of slipping, deflecting or popping out. For this, special support corners with bars are used. The resulting knot is fastened with wire using hardware. At the same time, nails should be hammered obliquely so that they enter the wood crosswise. The last nail must be driven in vertically.

In the case of a sliding fastening, alignment is performed using a special mechanism that allows you to move the rafter leg in the required direction. To do this, a tie-in is made on the supports, on which the Mauerlat is then laid. The structure is fixed, as in the previous case, with crossed nails. This method of arranging the connection nodes allows all nodes of the truss structure to move within certain limits.

Attention! Rigid fastening with inexperience of builders can lead to damage to the walls of the building.

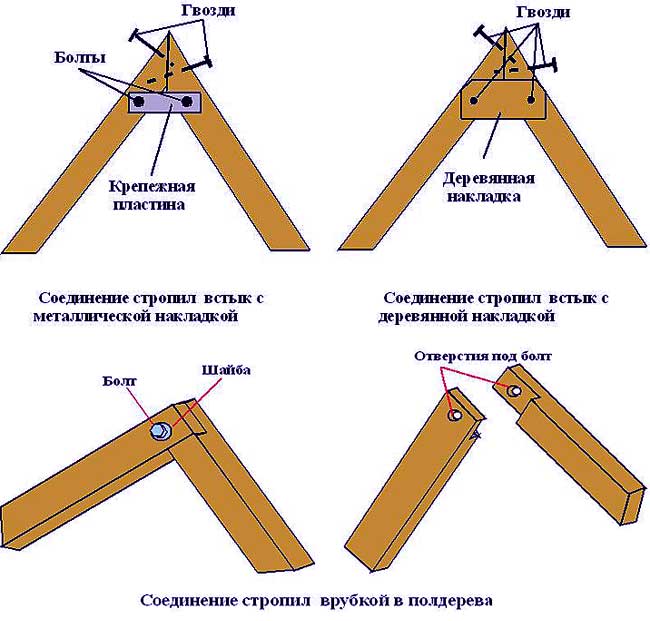

ridge knot

In this case, the fastening can also be made in two types - butt and overlap. With a butt joint, the top of the supports is cut with a bevel, as is the angle of the roof. They rest on the same undercut opposite supports. Fastening is carried out using nails, in the amount of two pieces. They are hammered from above at a certain angle. The seams that form between the supports are connected with metal plates or plates. In the second case, fastening is carried out by overlapping, not by end parts, but by lateral sections and fixed with bolts.

Conclusion

When performing work on the installation of the roof, the arrangement of the truss system should be given careful attention, avoiding disruption of technological processes. This will provide the structure with strength, durability and reliability.

The roof system is the part of the roof structure on the outside that is supported load-bearing structure. It includes a crate and a truss system. The triangle underlying this system should be a rigid and most economical structural element that contains the attachment points for the roof rafters.

The main characteristics of the nodes of the truss system

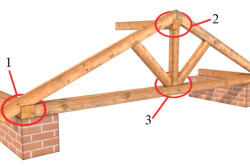

The main attachment points of the roof truss system are shown in fig. 1. They imply the presence of a rafter leg (Mauerlat - 1), a rafter leg (ridge run - 2), a rack (puffs - 3). The design of the truss system is the main load-bearing element of the roof.

All roof fasteners must be of sufficient strength to eliminate a significant degree of risk associated with roof collapse. The consequences of a mistake made when connecting elements can be the most unpredictable.

Figure 1. The main attachment points of the roof truss system: 1 - mauerlat, 2 - ridge run, 3 - puffs.

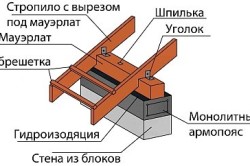

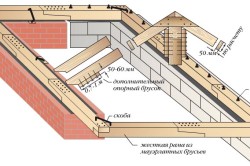

First, the rafters are installed on the Mauerlat if the building has brick walls. Similar nodes are provided for concrete blocks, then it is necessary to create a reinforced concrete stiffening belt, and it is necessary to insert studs into its design. Their location should be at a distance of 1 to 1.5 m from each other, and their diameter should be more than 14 mm. The top of the studs must be equipped with a special thread.

Mauerlat is drilled, making holes that are necessary for attaching elements to it. Each of the holes should be the same size as the diameter of the stud, and its pitch should correspond to the distance between the studs. A nut is put on each protruding end of the stud and tightened, which ensures the strength of the connection between the Mauerlat and the wall. The rafters should be connected to the Mauerlat in such a way that their weakening does not occur. bearing capacity.

Description of the main fasteners for mounting the truss system

If during the construction of the house a rounded log or timber was used, then it is not necessary to create an armored belt. produced on the upper beam or on the log of the wall. For this purpose, Mauerlat connections with rafters are used different ways notch (notch).

What fasteners fasten metal rafters:

- Plates.

- Fasteners LK.

- corners.

- Brackets WW.

- Self-tapping screws.

- Varieties of the corner of the KR.

- Wire ties.

- Mounting tape perforated TM.

- Bolts with nuts.

- Brackets WW.

If brackets are used when connecting the rafters to the Mauerlat, then they are not cut into the rafters, which helps to strengthen the bearing capacity. Metal brackets are usually produced, and the metal is galvanized and has a thickness of 0.2 cm. The brackets are strengthened with nails, anchor bolts or screws.

You can use the LK fastener by creating attachment points not only for rafters with a Mauerlat, but also for various other elements that make up the roof structure. The LK fastener is fixed to the wood, as are the brackets, with the exception of the use of anchor types of bolts.

Mounting perforated tape allows you to strengthen the connecting nodes in the construction of roofing systems. It is used not only to create stronger nodes, but also to strengthen elements for additional use in order to give rigidity or strength to the system as a whole. They fix the perforated mounting tape with screws or nails, so it is used to strengthen the structure of the rafter system of any roof, the integrity of which will not be violated.

With the use of KR corners and their various modifications, the attachment points are reinforced so that they can effectively participate in the connection of the Mauerlat and rafters. Ensuring appropriate strength to the roof units is permissible when using corners, which improves the load-bearing characteristics of the roof structure.

The use of connecting elements made of metal is not associated with inserting corners into the roof system. This will not cause a decrease in the bearing capacity of the roofing system. You can use corners for connection using screws or nails, the protrusions of which resemble a ruff.

How are the knots connected in the ridge part?

There are three main types of fastening in the ridge parts of the roofing system:

- Butt connection.

- Mounting on the basis of a ridge run.

- Ridge joint overlap.

For the purpose of fastening, in the first way, the ridge part is cut off from the upper edge at an angle that is the same as the angle of the roof slope. Then it rests on the necessary rafter, which should also be cut at an angle, but on the opposite side of the roof. A special template is sometimes used to trim corners.

Nails for connecting the rafters under the ridge should be 150 mm or more in size, they will need two pieces. Each nail is driven into the rafters at the top of the rafters at the appropriate angle. The sharp end of the nail usually enters the cut of the rafter with opposite sides. Strengthening the ridge joint can be achieved by applying a metal plate to it on the side or a wooden lining so that it is enough to pull it with bolts or nails.

The connection in the second way, that is, through the ridge run, is associated with the strengthening of the rafters on the ridge beam. The run is one of the additional support beams or beams, which is a support for rafters. It is located parallel to the ridge or Mauerlat. The method differs from the previous one in that a ridge beam is laid between the rafters, which are sawn at an angle, which is a laborious process, so this method is used less frequently.

A more common method is similar to the first, but it differs in that the fastening is overlapped, and the joint method is not used. The rafters should be in contact with the ends, and not the side surfaces. The rafters should be pulled together with a bolt or hairpin, nails. This connection is used by many masters in practice.

In general, it is possible to install rafters on a Mauerlat by creating structures for roof truss systems that are expansion or non-expansion. This determines the choice of the appropriate method of connecting the power plate and rafters, which can be similarly strengthened to the ridge.

The main shortcomings in the installation of attachment points for the truss system

The problem of choosing the method of attaching the truss system to the structure of the building is very important when creating attachment points. Often, when creating nodes, the Mauerlat serves as a support for the rafters. The fastening of the Mauerlat beam is carried out “tightly” with the help of anchor bolts to the reinforced stiffening belt.

A possible drawback is an unanchored stiffening belt, which can lead to the overturning of the Mauerlat beam and the violation of the stability of the roof truss system. There is a loosening of the roof, and the roof is sliding down. Due to erroneous placement of anchor bolts or incorrectly made holes, the fastening is no longer effective.

If the nuts are screwed onto the bolts with an overtightening, then the fastening assembly becomes fragile and is subject to rapid destruction. In this case, wire twisting is sometimes used to create an attachment point.

During the construction of the truss system, the safety of the joints should be observed.

For example, if the truss structure is combined with the floor without taking into account the bearing capacity of the attic floor, then this is the most dangerous moment that can lead to the destruction of the building.

If the tightening is changed to a precast concrete floor beam designed for bending, then the use of prefabricated reinforced concrete beams should be effective due to their rigid fixation in the reinforced floor stiffening belt, which is arranged using a reinforcing cage. Its axis must go in the same direction as the acting forces.

However, the presence of shortcomings in the process of creating a truss system, which is a carrier wooden structure overlapping, often occurs due to a misunderstanding of the functions performed by the puff and crossbar in the entire roofing system. The puff differs from the crossbar in that it is a longitudinal, and the crossbar is a transverse beam.

The construction of the truss system is associated with the creation of a spacer system that works on the principle of divergence at the bottom of the planes, which occurs under the influence of not only their own weight, but also the load that falls on the line of intersection of the planes, which should be prevented by the transverse beam, that is, tightening.

Getting to the roof device, you should find out all the points associated with the assumption of certain errors that occur when performing work on the installation of the truss system. The device of the roof of the house is associated with possible difficulties and shortcomings that do not allow achieving the goal.

Mauerlat is one of the main elements of the roof structure. Rafters are attached to it. The operational period of the entire roof depends on the quality creation of the truss structure.

The main ways of supporting rafters

There are several technologies for supporting rafters on the Mauerlat. It is possible to carry out a rigid fixation of the structure. It does not allow any displacement of the rafter leg. To do this, use a hemmed beam, which prevents the rafters from slipping at the point of support, and metal corners that eliminate any lateral shift of the structure.

The sliding joint of the rafter leg is used in wooden houses. Moreover, the main element for its emphasis is the upper crown, and not the Mauerlat. To prevent damage to the roof, the rafter support assembly is made as free as possible. To do this, use a sliding support, which, when the frame shrinks, is displaced along the guide fixed on the leg.

The sliding support unit can also be made using a different technology. A notch is made in the rafters, which should adjoin the upper crown of the log house. To fix the beams, it is permissible to use any fasteners: staples, nails or steel plates.

Fasteners for installation work

To qualitatively connect the nodes of the rafters with the Mauerlat, you will need materials and tools such as:

- dry timber;

- boards;

- axe;

- hacksaw;

- hammer;

- roulette;

- plumb;

- level;

- screwdriver;

- drill;

- Bulgarian.

Particular attention should be paid to the presence of all fasteners. Beam consoles are fixed using galvanized steel beam brackets, which do not reduce the bearing capacity of the structure. Brackets do not need to be cut into the beams.

You also need to buy perforated mounting tape, which will strengthen the Mauerlat nodes. With its help, a strong connection of all structural elements is made. The tape also does not crash into the beams. For its reliable fixation, nails and self-tapping screws are used.

In addition to brackets and perforated tape, in order to securely support the rafters to the Mauerlat, you should purchase:

- universal bar connectors;

- fasteners for rafters;

- mortgage supports;

- wire rod;

- steel corners;

- rack mount;

- self-tapping screws;

- nails;

- staples;

- plates;

- galvanized nails;

- studs with washers and nuts;

- anchor bolts.

Creating a ridge and installing the bottom of the rafters

Installation work begins with the ridge part of the roof structure. You can install the rafters in one of three ways:

- butt;

- for the run;

- overlap.

Butt-joining the structure involves cutting the upper part of the rafter leg. This is done at an angle that is equal to the slope of the roof slope. On the skate, a pair of legs joins. To obtain the same support node for the Mauerlat elements, you should use a ready-made template.

A feature of fixing the rafters on the run is the presence of a ridge beam. This option for arranging the Mauerlat is characterized by increased reliability. But often such a rafter support system provides for the installation of additional supporting structures, which will lead to a decrease in the functionality of the attic. Naturally, this method is not suitable for small roofs.

The technology for installing overlapping rafters is in many ways similar to installing them on a ridge run. The main difference is that the connection of the upper part of the legs overlaps. This leads to a strong connection of the structure, since the studs hold two elements at once.

The connection of the lower ends of the rafters is carried out depending on the material of the walls. In the presence of wooden housing construction, the upper wall trim can act as a supporting element. If foam blocks (or aerated concrete) were used during the construction of the house, then the rafters are supported on the Mauerlat.

The device of the reinforced concrete belt - optimal solution in case of using masonry building materials. This technology does not provide for the creation of any methods of fixing the truss system. Vertically located anchor bolts act as fasteners for the timber. The main thing is that when pouring the concrete solution, the studs are located in a strictly vertical position.

Connection of rafters with beams and Mauerlat

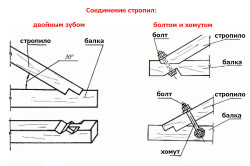

After fixing the upper and lower parts of the rafters, they should be fixed to the beams. It is clear that you can connect the rafters to the beam with just nails. But this is not the best solution. Such a mount will not be as reliable as possible. To prevent slipping of all elements, the truss structure is fixed to the beams by using “thorn” and “tooth” connections.

In the presence of a steep roof slope (more than 35º), cutting technology is used with a single tooth. A tooth with a spike is made at the bottom of the rafter. Nests created in the beam should be at least 30% of the beam thickness deep. Device rafter connections carried out at a distance of 0.3-0.4 m from the extreme part of the beam. This prevents the splitting of the beams resulting from the high load from the pressure of the legs.

When arranging a roof with a slope of up to 35º, the installation of rafters is carried out by expanding the mating area of \u200b\u200bthe main structural elements. Usually the rafter leg is covered with a beam. For this purpose, holes are cut in the rafter leg for two teeth:

- spike with emphasis;

- one more emphasis.

The depth of the cut when fixing the rafters to the beam is within 30% of the thickness of the beam.

Better connections can be obtained by using bolts or clamps. This technology involves the use of wire loops, with the help of which the knot is fixed to anchor bolts located in the wall of the building.

Relying on the Mauerlat is the most common option for fixing the lower part of the rafters. A cutout of such a size is made in the rafter leg so that it can be put on the Mauerlat without any problems. Otherwise, during the operation of the roof, a displacement of the bar may occur.

In some cases, the Mauerlat must be “equipped” with a reverse notch. It depends on the type of wood from which the beam is made. If hardwood was used for its production, then a slot is made, which, in combination with the recess of the rafters, will create a lock element. When making a beam from coniferous wood, a cutout is not required, as it will lead to a weakening of the structure.

The most acceptable option for the Mauerlat is the rigid connection of the truss system.

This technology can be done in one of two ways:

- with the help of hemmed bars and corners made of metal;

- by arranging saddles on rafters.

The first option is that a support beam is used to place the rafters on the Mauerlat. Rigid support of the rafter leg is made. Reliable fixation of the structure is carried out by metal corners. This prevents lateral movement of the structure.

The second option is more popular. For fasteners, nails are used that are directed towards each other and hammered at an angle. Two hammered nails cross. Then another nail is driven in. The third nail should be in a vertical position. The fastening unit made will be characterized by maximum rigidity if additional fastening is carried out using wire rod.

At the beginning of planning mansard roof a rafter system is selected that plays the role supporting structure. The required type of truss system is determined based on the type of roof.

Depending on the system chosen, these may be wooden bars, used as a roof frame that holds back the composite building materials of the entire structure, or specific elements that create supports called rafters. Before starting work, the wooden components are impregnated with special compounds that protect the roof from fire and decay. The durability of the roof directly depends on the quality of this procedure.

Varieties of truss systems and the arrangement of their nodes

The rafter system is divided into two main types: layered and. Since the connection nodes in each of the systems have different characteristics, certain type rafters are selected based on the properties of the preferred roof, including its architectural features.

The main factors in choosing the right type of system:

- overall functionality of the roof;

- pressure force of roofing building materials on the structure;

- the prevalence and frequency of precipitation in the area where the house is located.

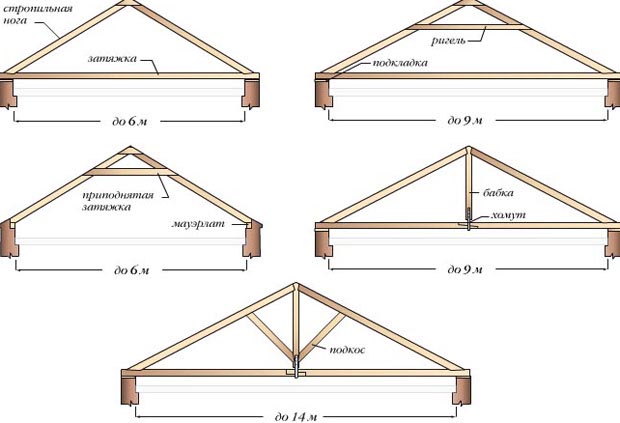

The hanging type of rafters does not have supports located in the gaps. For this reason, an increased thrust occurs, which is transmitted horizontally to the walls of the building. To reduce this figure, a protracted element made of wood or metal is introduced into the support assembly, designed to combine the rafter legs. Thus, the nodes of the hanging rafters take the form of a triangle. The tightening element is located at the base of the legs, it performs the function of a crossbar (most often used in gable roof structures) and works on bending and compression. The strength of the connection with the base of the supports depends on the height of the tightening element.

The layered type of rafters is often equipped in buildings where there is a central supporting column or load-bearing wall. The rafters rest with their limbs on the sides of the building, and the central part rests on a column or other support inside the house. Such a structural assembly is designed for flexural functioning. Layered supports create less load on the component parts of the building, so their installation is not as laborious as in the case of hanging rafters. In addition, it does not require large material costs.

There are also options for arranging the roof, combining both types of rafters. In this case, each type alternates, that is, zones without load-bearing walls are equipped with hanging rafters, and areas with the necessary supports are layered.

Competent arrangement of the truss system

The main factor in the high strength of the roof in the future construction is the competent arrangement of all nodes and reference points.

In the case of rafters for a mansard roof, at least 3 strong points are assumed. This value may change if the span exceeds standard limits. For example, if the span is not more than 10 m, only one additional support will be required.

The hanger assembly is assembled based on span dimensions. On small spans, the protracted element is most often replaced by a crossbar. With large spans, the lingering elements sag, and the supports bend.

Thus, dangling nodes can have the following differences regarding the span size:

Figure 1. Diagram of the Mauerat device.

- 9 m. Supports must be restrained with a wooden block, which is installed perpendicular to the attic floor. In the base area, it is reinforced with staples, and the protracted elements are fastened with special clamps.

- 13 m. Fastening is carried out with the help of struts, which abut against the base with the top, and with the lower part against the perpendicular beam. The interval between the supports should not be more than 5.5 m.

- 17 m. The base must be strengthened with special devices. A trussed structure is used for the top: the protracted elements are attached to two wooden bars, and a crossbar is mounted between them.

Knot attachment methods

Regardless of whether it is required to replace the existing rafter system or build it from scratch, it is necessary to follow a certain set of rules when attaching its nodes.

First of all, the simplest fastening of the crossbeam and the base of the support should be avoided, as this can have a devastating effect on the entire roofing system.

Figure 2. Fastening the rafter leg to the Mauerlat.

In other words, from the load created by building materials or precipitation, the ends of the supports slide off, and the rafter system is damaged. This leads to its complete collapse. To prevent this outcome, it is necessary to increase the reliability of these nodes. This is achieved using the following types of fastening:

- teeth into a tenon;

- point-blank teeth;

- emphasis on the end of the crossbar.

One or two teeth can be used depending on the slope. To increase the reliability of the connection, you can create additional fasteners using metal corners.

Roof framing attachment points

The main attachment points of the truss system are:

- beam;

- Mauerlat;

- ridge.

Beam mount

Figure 3. Scheme of the ridge connection of the truss system.

In the rafter leg, teeth are created into a spike, and a nest is cut out in the crossbar, which corresponds to the cut teeth. In this case, the nest should occupy no more than 30% of the entire thickness of the crossbar.

If lightweight materials were used in the construction of the roof, and its slope is less than 35 °, the bases of the supports are placed so that their area of support is much larger than the beam. This can be achieved by using a mortise with two teeth in 2 studs, a stop (with or without a stud), and two studs in the lock.

The nodes of the system are fastened either with hardware with metal corners, or with wooden bars, overlays and spikes.

Mauerlat mount

There are 2 technologies for Mauerlat fastening of supports: rigid and sliding (Fig. 1).

In the first case, a strong connection is established between the rafter and the Mauerlat without the possibility of slipping, deflecting and popping out. This is achieved by placing special corners with a support bar. The formed knot must be fastened with a reliable wire using hardware. Nails are hammered under a certain slope from the side so that they are in the Mauerlat in a crossed state. The last nail is nailed vertically. This method is the most popular.

In the second case, fastening is carried out using a special mechanism that allows a certain element (in this case, the rafter) to move in the right direction (Fig. 2).

To create such a connection, you will need to make a tie-in on the supports, and then lay them on the Mauerlat. As in the previous case, both parts of the knot are fixed with two crossed nails and one vertical one on top. The boards are fixed to the Mauerlat with metal brackets. After that, the support base is extended beyond the wall and fastened with plates and sleds. Thus, the emphasis is on the Mauerlat, but all components of the truss system can move within acceptable limits.

This method is most often used in the construction of the roofing system of wooden buildings (logs, log cabins), which are prone to subsidence. It is worth remembering that with rigid fastening there is a possibility of damage to the walls of the building.

Ridge mount

Such a knot can be created in two ways: butt and overlap (Fig. 3).

The first method involves cutting the top of the supports at the same slope as the corner of the roof. They rest against opposite supports, which also need to be cut. The fastening is created using two nails (150 mm) hammered from above at a certain angle so that they are proportionately located inside each rafter. To increase reliability, the seams between the supports are fastened with wooden plates or metal plates.

The second method is the most popular. It is distinguished from the first method by the overlapping method. In this case, the supports are connected not by the ends, but by the side parts, after which they are fixed to the bolts.