Static electricity (according to GOST 12.1.018) is a set of phenomena associated with the occurrence, preservation and relaxation of free electric charge on the surface (or in the bulk) of dielectrics or on insulated conductors.

The appearance of static electricity charges. Static electricity charges are formed under a wide variety of industrial conditions, but most often when one dielectric rubs against another or dielectrics against metals. Electrical charges can accumulate on rubbing surfaces and easily flow into the ground if the physical body is a conductor of electricity and is grounded. Electric charges are retained on dielectrics for a long time, which is why they are called static electricity.

Static electricity arises as a result of complex processes associated with the redistribution of electrons and ions when two surfaces of heterogeneous liquid or solid substances that have different atomic and molecular forces of surface attraction come into contact.

A measure of electrification is the charge that a given substance has. The intensity of charge formation increases with increasing speed of movement of materials, their resistivity, contact area and interaction force. The degree of electrification of a charged body characterizes its potential relative to the ground.

In production, the accumulation of static electricity charges is often observed when: friction of drive belts on pulleys or conveyor belts on shafts, especially with slipping; pumping flammable liquids through pipelines and loading petroleum products into containers; movement of dust through air ducts; crushing, mixing and sifting dry materials and substances; compression of two dissimilar materials, one of which is a dielectric; mechanical processing of plastics; transporting compressed and liquefied gases through pipes and their flow through openings, especially if the gases contain finely atomized liquid, suspension or dust; movement of a vehicle, trolleys on rubber tires and people on a dry insulating coating, etc.

The strength of the electrification current of the flow of petroleum products in pipelines depends on the dielectric properties and kinematic viscosity of the liquid, the flow speed, the diameter of the pipeline and its length, the material of the pipeline, the roughness and condition of its internal walls, and the temperature of the liquid. With turbulent flow in long pipelines, the current strength is proportional to the speed of the fluid and the diameter of the pipeline. The degree of electrification of moving dielectric belts (for example, conveyor belts) depends on the physicochemical properties of the materials in contact, the density of their contact, speed of movement, relative humidity, etc.

Danger of static electricity. Spark discharges of static electricity pose a great fire and explosion hazard. Their energy can reach 1.4 J, which is quite enough to ignite steam, dust and gas-air mixtures of most flammable substances. For example, the minimum ignition energy of acetone vapor is 0.25 10-3 J, methane 0.28 10-3, carbon monoxide 8 10-3, wood flour 0.02, coal 0.04 J. Therefore, in accordance with GOST 12.1.018, the electrostatic safety of an object is considered achieved only if the maximum energy of discharges that can occur inside the object or from its surface does not exceed 40% of the minimum ignition energy of substances and materials.

Electrostatic charge generated during some manufacturing processes can reach several thousand volts. For example, when sand and dust particles rub against the underbody while the car is moving, a potential of up to 3 kV is generated; when pumping gasoline through a pipeline - up to 3.6 kV; when pouring electrifying liquids (ethyl alcohol, gasoline, benzene, ethyl ether, etc.) into ungrounded containers in the case of a free fall of the liquid stream into the container being filled and a high flow rate - up to 18...20 kV; when the conveyor belt rubs against the shaft - up to 45 kV; when transmission belts rub against pulleys - up to 80 kV.

It should be borne in mind that a potential of 300 V is sufficient to explode gasoline vapors; at a potential difference of 3 kV, flammable gases ignite, and at 5 kV, most combustible dusts ignite.

Static electricity can also accumulate on the human body when wearing clothes made of wool or artificial fiber, moving on a non-conductive floor covering or wearing dielectric shoes, or coming into contact with dielectrics, reaching in some cases a potential of 7 kV or more. The amount of electricity accumulated on people can be quite sufficient for a spark discharge upon contact with a grounded object. The physiological effect of static electricity depends on the energy released during the discharge and can be felt in the form of weak, moderate or strong pinpricks, and in some situations - in the form of mild, moderate and even acute cramps. Since the current strength of the static electricity discharge is negligible, in most cases such exposure is harmless. However, the reflex movements of a person arising from this phenomenon can lead to serious injuries due to a fall from a height, the capture of protective clothing or individual parts of the body by unguarded moving parts of machines and mechanisms, etc.

Static electricity can also disrupt the normal flow of technological processes and interfere with the operation of electronic automation and telemechanics devices, and radio communications.

Measures for protection against static electricity are carried out in explosion and fire hazardous rooms and areas of open installations related to classes B-I, B-I6, B-II and B-IIa. In rooms and areas that do not belong to specified classes, protection is carried out in those areas of production where static electricity negatively affects the normal flow of the technological process and product quality.

Measures to protect against static electricity are aimed at preventing the occurrence and accumulation of static electricity charges, creating conditions for the dispersion of charges and eliminating the danger of their harmful effects.

Preventing the accumulation of static electricity charges is achieved by grounding equipment and communications on which they may appear, and each system of interconnected machines, equipment and structures made of metal (pneumatic dryers, mixers, gas and air compressors, mills, closed conveyors, filling and draining devices liquids with low electrical conductivity, etc.), are grounded in at least two places. Pipelines located in parallel at a distance of up to 10 cm are connected to each other by metal jumpers every 25 m. All mobile containers temporarily under loading or draining of liquefied flammable gases and flammable liquids are connected to a ground electrode during filling. Gas stations and automobile tanks are grounded with a metal chain, maintaining a length of contact with the ground of at least 200 mm.

Reducing the intensity of the occurrence of static electricity charges is achieved by appropriate selection of the speed of movement of substances, excluding splashing, crushing and atomization of substances, removal of electrostatic charge, selection of friction surfaces, purification of flammable gases and liquids from impurities. Safe transport speeds of liquid and dusty substances depend on their specific volumetric electrical resistance ρv. Thus, for liquids with ρv ≤ 105 Ohm m, the permissible speed should be no more than 10 m/s, at 105 Ohm m< pv < 109 Ом· м — до 5 м/с, а при ρv >109 Ohm m velocities are set for each liquid separately, but, as a rule, no more than 1.2 m/s. When supplying liquids to tanks, it is necessary to prevent their splashing, atomization and violent mixing. The filling tube must be extended to the bottom of the vessel with the stream directed along its wall. When initially filling the tanks, liquid is supplied at a speed not exceeding 0.5...0.7 m/s.

The best way to reduce the intensity of accumulation of static electricity charges in belt drives is to increase the electrical conductivity of belts, for example, by stitching the inner surface of the belt with thin copper wire in the longitudinal direction or lubricating its inner surface with conductive compounds (containing, for example, soot and graphite in a ratio of 1:2 .5 by mass, etc.). You should also pay attention to adjusting the tension of the belts and, if possible, reducing their speed to 5 m/s.

If it is not possible to prevent the accumulation of static electricity charges by grounding, then measures should be taken to reduce the volume and surface dielectric resistance of the materials being processed. This is achieved by increasing the relative air humidity to 65...70%, chemical surface treatment, the use of antistatic substances, the application of electrically conductive films, reducing the speed of movement of charging materials, increasing the cleanliness of the processing of rubbing surfaces, etc.

If it is impossible to use means of protection against static electricity, it is recommended to neutralize the charges by ionizing the air in the places where they arise or accumulate. For this purpose, special devices are used - ionizers, which create positive and negative ions around an electrified object. Ions, which have a charge opposite to that of the dielectric, are attracted to the object and neutralize it. To remove static electricity from the human body, conductive floors or grounded areas, work platforms, stair handrails, instrument handles, etc. are provided; provide workers with conductive shoes with a sole resistance of no more than 108 Ohms, as well as antistatic workwear.

The study of the problem of static electricity is caused by the increasingly widespread use of polymer materials, synthetic fabrics and fibers that can accumulate large charges of static electricity during processing or operation. The harmful manifestation of static electricity entails a variety of consequences:

– firstly, at high potentials of static electricity, reaching tens of thousands of volts, in an explosive or fire-hazardous environment, explosions and fires occur as a result of spark breakdowns, causing casualties and severe injuries;

– secondly, static electricity has an adverse effect on the health of those working with electrified materials;

– thirdly, in a number of industries, due to high electrification, technological processes are disrupted, defects appear, and labor productivity decreases.

Static electricity poses the greatest danger to industries associated with the processing and transportation of flammable substances and materials, especially in explosive air environments. The use of synthetic polymers and dielectrics in explosive and fire hazardous conditions is almost always associated with a real threat of ignition, since thermal energy, released during a spark discharge, many times exceeds the minimum ignition energy of air mixtures - methane, acetylene, gasoline vapor, acetone and many other substances.

In addition to the harmful effects on the human body and the immediate danger from explosions and fires, static electricity in some cases causes a decrease in labor productivity. Harmful electrification is observed in many enterprises: in the chemical, printing, textile and light industries, oil refining and oil production industries. Static electricity is a problem in almost half of technological processes. The danger of excessive accumulation of electrostatic charges limits the loading speed of petroleum products to 1 m/s and forces many technological processes (for example, the production of polypropylene) to be carried out under the pressure of inert gases, which significantly reduces productivity and increases production costs. Electrification leads to breakdown of synthetic pipelines, failure of product seals, failure of semiconductor devices, exposure of photosensitive materials, accumulation of dust, and reduction in product quality. The scale of the harmful and dangerous manifestations of static electricity is such that protection against it has become one of the most pressing problems.

Static electricity causes a lot of damage. Therefore, it is necessary to develop and implement effective measures to protect against electrification in various industries. There are already a sufficient number of methods and means to prevent unwanted electrification of substances and materials. Of the variety of existing measures to protect against static electricity, the most effective are the following: increasing air humidity; grounding of equipment and people; use of antistatic additives; limiting the speed of transport of a substance; neutralization of static electricity charges.

It has been established that with an increase in air humidity, a thin film of moisture with salts dissolved in it forms on the surface of materials. This film has semiconducting properties, which promotes charge dissipation. But this effect is not observed if water vapor is not adsorbed on hydrophobic surfaces (polymer materials, fibers, etc.) or the air temperature is work area higher than the temperature at which the film can be retained on the dielectric, and also when the speed of movement of the dielectric is greater than the rate of formation of the adsorbed water film (this depends on the chemical structure of the substance and the degree of surface contamination). In the same place where an increase in relative air humidity is effective means combating electrification, many studies have shown that when air humidity increases to 65–80%, electrification is almost completely eliminated. In practice, humidification in rooms is carried out using air conditioning devices, special humidifiers, and in some cases through periodic wet cleaning.

In GOST 12.4.124-83 SSBT. “Means of protection against static electricity. Are common technical requirements» describes various technical means to protect people from static electricity.

A mandatory measure to eliminate electrostatic charges from metal equipment is grounding. Ungrounded equipment is a source of increased danger, since the spark energy metal structures many times higher than the discharge energy from the dielectric.

Equipment is considered electrostatically grounded if the leakage resistance at any point under the most unfavorable conditions (low air humidity, etc.) does not exceed 10 6 Ohms. Electrostatic grounding conductors are not subject to such stringent requirements as when grounding equipment in order to protect people from electric shock. The resistance of the grounding conductor when discharging electrical charges is allowed up to 100 Ohms. The reliability of the connection of equipment with grounding conductors is usually ensured by welding, less often by bolting. By doing flange connections The resistance between adjacent flanges should not be lower than 10 Ohms, and it is not necessary to use special jumpers. When installing temporary grounding (tanks, measuring devices, etc.), the choice of the type of grounding is determined only by their mechanical strength.

In some cases, it is necessary to ground a person who may become electrified during work or due to electrostatic induction. To do this, use electrically conductive floors, grounded areas near workplaces in combination with conductive or semi-conductive shoes. Electrically conductive floors include concrete, foam concrete and xylolite floors that are not contaminated with paint, oils and other insulating substances. If the relative humidity is high enough, wood floors also dissipate static electricity well. If grounded metal platforms are used near the workplace, then it is necessary to completely exclude the possibility of a person touching live parts of dangerous voltage.

The possibilities of using special protective clothing are described in GOST R EN 1149-5-2008 SSBT “Special protective clothing. Electrostatic properties. Part 5. General technical requirements".

You can impart antistatic properties to non-conductive floors covered with linoleum, relin, and polyvinyl chloride tiles by wet cleaning with a 10–20% aqueous solution of calcium chloride. But increasing the electrical conductivity of floors is ineffective without the use of conductive shoes. Shoes are conductive: 1 - with a sole made of slightly moistened leather or semi-conductive rubber; 2 - pierced with copper, brass or aluminum rivets that do not spark when walking.

When processing and using materials with a specific electrical resistance of more than 106–107 Ohm cm (for organic liquids more than 109–1010 Ohm cm), grounding of metal structures is only

additional measures to remove electrostatic charges.

It should be noted that liquid and gaseous dielectrics, which have a very high resistivity (above 1017–1018 Ohm cm), are practically not electrified. “Absolutely pure” materials that do not contain impurities have such high resistivities. In this regard fine cleaning substances can be recommended as one of the measures to protect liquids and gases from electrification.

In most cases, an effective means of protection against static electricity is to reduce the volumetric resistivity of substances. The most common method is the introduction of conductive compositions into the structure of the material during its manufacture. In this way, conductive rubbers, linoleums, antistatic paints and varnishes, and non-electrifying plastics were obtained. Carbon black, graphite, powdered copper, silver, petal nickel and other additives are used as electrically conductive compositions. To increase the surface conductivity of solid dielectrics, various pastes, compositions, and emulsions have been developed that are applied to the electrifying surface. Metallization of surfaces and coating with chloride and fluoride compounds are successfully used.

Charges are sometimes removed from the outer surface of hoses and pipelines by winding a spiral of copper or steel grounded conductor onto them. Conveyor belts and some fabrics are stitched with thin electrical conductors, and antistatic fabrics are also used.

An effective way to combat static electricity in textiles and a number of other industries is to mix (combine) electrified fibers or select contact pairs. For example, in fabrics made from a combination of two electrified fibers - nylon and dacron - the desired effect is achieved by the fact that each fiber individually, during friction, is electrified by mutually neutralizing charges of opposite signs. By selecting contact pairs in this way when manufacturing parts of technological equipment, it is possible to eliminate the manifestations of static electricity in many industries. To reduce electrostatic charges, they sometimes take the path of reducing the area of contact of the electrified material with work surface machine parts and devices. In this case, the surfaces of work tables, machine shafts and other equipment are covered with a mesh or made ribbed.

As is known, a reduction in electrification can be achieved by reducing the speed of technological processes, but this measure is subject to modern production extremely undesirable. Therefore, to eliminate electrification when transporting electrified liquids, the speed is limited in only one of the pipeline sections. This event is known as “electrostatic relaxation.” The principle of relaxation is based on keeping a dielectric liquid for some time at relative rest in a relaxation tank (a section of a pipeline with a much larger diameter). While the liquid is in the relaxer, the charges manage to flow onto its grounded walls. It has been established that relaxation containers remove electrostatic charges by 95–98%.

When filling tanks with dielectric liquids, charges may form when splashed. Therefore, the filling of containers begins at a low speed of movement of electrified liquids with a gradual increase in speed as the reservoir is filled. Sharp bends in the pipelines should not be allowed and there should be no protruding parts inside them, as this leads to additional electrification of the transported liquids.

Static electricity neutralizers represent an independent group of protective equipment. The operating principle of all neutralizers is based on the generation of ions in the zone of charged material. These ions are attracted by the field forces of the charged substance and neutralize the charges. Air ionization occurs when irradiated with ultraviolet or x-rays, thermal, infrared or radioactive radiation, as well as due to corona discharge.

Currently, to ionize the air, it is usually used

They include radioisotope α- and β-radiation, electric corona discharge and the so-called sliding discharge. In explosion-proof industries, ionizers with corona discharge on their tips are usually used to combat electrification. They provide maximum ionization density. Depending on what is more important in this case to ensure - a minimum residual charge or neutralization of a large amount of electricity - electric or induction neutralizers are used.

An induction neutralizer is a conductive or dielectric rod on which grounded needles or wire whisks are attached. When installing the neutralizer over a charged surface, such a strong force is created at the ends of the needles electric field, that impact ionization occurs, as a result of which the resulting ions neutralize the charges on the surface of the electrified material. The main difference between electric neutralizers and induction ones is that a high (10–15 kV) direct or alternating voltage is supplied to the needles from a special source, which increases the efficiency of neutralization. The effectiveness of neutralizers is most often assessed by the magnitude of the ionization current flowing through the neutralizer to grounded equipment. This current is greater, the higher the level of electrification of the material.

Sometimes a thin conductor stretched near a charged surface or in the path of movement of liquids and bulk materials is effectively used as a neutralizer. In most cases there is no particular need to reduce the degree of electrification to zero. For various substances and materials, there is a minimum charge density that does not affect the course of the technological process. Therefore, the work of a particular neutralizer can be assessed by the values of the initial (before the neutralizer) and final (after the neutralizer) charge densities. In practice, for a specific type of neutralizer, the dependences of the initial and final charge densities can be constructed for various process parameters.

The so-called combined neutralizers, which combine radioisotope and induction neutralizers in one device, are becoming increasingly widespread. At the same time, the efficiency of neutralization increases significantly, since large charges are reduced by induction, and small ones by radioisotope neutralizers.

The scope of application of electrical and radioisotope neutralizers used to ionize the air flow, which is pumped into the area where it is necessary to reduce electrostatic charges, has expanded significantly. This method makes it possible to ensure the explosion safety of the use of even high-voltage neutralizers. However, the efficiency of neutralizers with injection of ionized air is low due to the recombination of ions in the air flow. Even a sharp increase in the ion density directly at the source cannot significantly change the range of action of such a neutralizer, since the intensity of recombination increases with increasing density. The most promising method, when it is necessary to create an ionization region extended in one direction, should be considered the use of a laser.

In cases where the removal and neutralization of static electricity charges is very difficult, a method can be used to prevent dangerous discharges without removing or neutralizing the charges. This method is based on the mechanism of electrical discharge, for the occurrence of which it is necessary that the potential difference between a charged body and grounded parts of equipment does not exceed the level determined by the electrical strength of air. To reduce the potential of a charged surface, they strive to increase the specific electrical capacitance of the charged surface (or charged particles) relative to the ground. As the capacity of a body increases, the charge energy from this body correspondingly decreases and the danger of ignition of steam-gas-air mixtures decreases. Sometimes this method is used to reduce the risk of discharges from a person. For this purpose, grounded areas are created in work areas (sometimes under an insulating floor covering), which serve to increase human capacity. Studies have shown that in this way it is possible to increase a person’s capacity by 3–4 times.

Sometimes the usual measures are used to prevent the possibility of ignition - reducing the concentration of flammable substances below the lower explosive limit, creating an inert gas atmosphere, using electrostatic screens, replacing flammable substances with non-flammable ones.

It should be noted that the introduction of any measure to prevent electrification should be preceded by a thorough study of production conditions. As a rule, the most effective is the use of several of the considered methods at once.

The existence of a person in a specific environment is associated with the impact on him (and on the surrounding conditions) of electromagnetic fields. What conclusion can be drawn in the case of the presence of stationary charges? This means we are talking about electrostatic fields.

Main danger

In this case, the nervous system of people experiences a heavy load. This is due to the fact that electric fields from excess charges affect the body, clothing and objects. The cardiovascular system of the body also reacts to these phenomena.

basic information

What is static electricity? It occurs when intramolecular or atomic equilibrium is disrupted. This is due to the loss or gain of an electron. Normally, an atom is characterized by an equilibrium state. This is explained by the same number of negative and positive particles. We are talking about electrons and protons. The former easily move from one atom to another. In this case, the formation of negative and positive ions occurs. Thus, static electricity occurs when such an imbalance occurs.

The main reasons for the appearance

Static electricity can occur under the influence of a number of factors, including the following:

More about the dangers

Electrification of various materials can pose a threat to people. In this regard, everyone needs to know the rules of protection against static electricity. The main danger is the possibility of a spark discharge. This applies to both an insulated conductive object and an electrified surface.

Possibility of discharge

This occurs when the strength of the corresponding field above the surface of a conductor or dielectric (which is due to the accumulation of charges on them) has reached a critical value. The latter is sometimes called punching. This value for air is approximately 30 kV/m.

Other dangers

Due to spark discharges, flammable mixtures may ignite. This will happen when the energy released is greater than that which contributed to the start of the fire. There is also general meaning. This energy must be higher than the minimum similar parameter for ignition of the combustible mixture.

Possible consequences

Why do you need to know the basic rules of protection against static electricity? In some cases, its effects may cause unwanted nerve and pain sensations. Sometimes this leads to involuntary sudden movement of a person. As a result, he may receive some kind of mechanical injury. In this case, a person’s own static electricity plays an important role.

Control Features

There is a corresponding GOST. Static electricity can indeed be extremely dangerous. To reduce risks, permissible strength levels of the corresponding fields have been established. All this must be strictly controlled in the workplace. It is also necessary to comply with sanitary and hygienic standards. These requirements apply to fields that arise due to the electrification of certain materials, as well as during the use of installations. In the latter case, a high DC voltage is implied. Compliance with them is the main protection against static electricity. GOST determines the permissible levels of tension in the workplace. It is also written there General requirements to protective equipment and control. As for the permissible levels of electric field strength, they are set taking into account the time employees spend at their workplaces.

Choosing the right tools

Anti-static electricity protection can be arranged different ways. First of all, you need to take into account the following:

- Features of technological processes.

- Indoor microclimate.

- Physico-chemical properties of processed materials.

Thus, an approach to organizing security activities is being developed. Removing static electricity can be done in several ways:

- Elimination of formed charges.

- Reducing their intensity.

Regarding the latter case, the answer to the question of how to remove static electricity is as follows: this is achieved by reducing the force and speed of friction, increasing the conductivity of materials and differences in their respective properties. The following are practical recommendations:

The most effective methods

Charges can be generated by splashing, spraying and sloshing of certain liquids. Ideally, such phenomena will be eliminated completely. If this is not possible, then you need to at least limit them as much as possible. For example, when filling tanks with dielectric liquids, a free-falling jet cannot be used. In this case, the drain hose is directed along the wall to avoid splashing. Ideally, it is possible to lower it below the liquid level. The lower the electrical conductivity of materials, the higher the intensity of charge formation. Thus, it is advisable to increase the previously specified parameter of the existing elements. This can be done by introducing antistatic suction cups. Accordingly, special linoleum should be used to cover the floors. Carrying out periodic antistatic treatment of carpets is very desirable. This also applies to synthetic fabrics. It is desirable that contacting substances and objects are made of similar materials. In this case, contact electrification is also excluded. For example, polyethylene powder should be stored in barrels made of similar materials. It is better to transport and pour it only using the appropriate pipeline and hose. In some cases this may not be possible. Then it is permissible to use materials that are similar in dielectric properties. So, we can draw a small conclusion that to protect against static electricity, it is necessary to use weakly or non-electrified materials. You should also strive to eliminate the following phenomena when working with dielectric liquids:

- Splashing.

- Spattering.

- Spraying.

- Friction.

If there is no possibility of complete elimination, then you need to at least limit them as much as possible.

Additional methods

Moist air has sufficient conductivity for the resulting charges to flow through it. Thus, in the appropriate environment they practically do not arise. Based on this, air humidification is the most common and simplest way to combat static electricity. There are also other security methods. We are talking about air ionization. It is also a common method of dealing with electrical charges. The fact is that ions help neutralize them. They are produced by a special device. A household ionizer has many advantages. First of all, it helps to improve the aeroionic composition of the indoor air environment. This eliminates electrical charges that occur on clothing, synthetic flooring and carpets. As for production, the most powerful ionizers are used there. There are various designs. However, electric ionizers are the most common.

The daily activity of any person is connected with his movement in space. At the same time, he not only walks, but also travels by transport.

During any movement, a redistribution of static charges occurs, changing the balance of internal equilibrium between the atoms and electrons of each substance. It is associated with the process of electrification, the formation of static electricity.

U solids The distribution of charges occurs due to the movement of electrons, and in liquids and gases - both electrons and charged ions. All of them together create a potential difference.

Reasons for the formation of static electricity

The most common examples of the manifestation of static forces are explained in school during the first physics lessons, when they rub glass and ebonite rods on woolen fabric and demonstrate the attraction of small pieces of paper to them.

There is also known experience in deflecting a thin stream of water under the influence of static charges concentrated on an ebonite rod.

In everyday life, static electricity manifests itself most often:

when wearing woolen or synthetic clothing;

walking in shoes with rubber soles or woolen socks on carpets and linoleum;

using plastic items.

The situation is aggravated by:

dry indoor air;

reinforced concrete walls from which multi-storey buildings are made.

How is a static charge created?

Usually physical body contains an equal number of positive and negative particles, due to which a balance is created in it, ensuring its neutral state. When it is violated, the body acquires an electrical charge of a certain sign.

Static means a state of rest when the body does not move. Polarization can occur inside its substance - the movement of charges from one part to another or their transfer from a nearby object.

Electrification of substances occurs due to the acquisition, removal or separation of charges when:

interaction of materials due to friction or rotation forces;

sudden temperature change;

irradiation in various ways;

dividing or cutting physical bodies.

They are distributed over the surface of an object or at a distance from it of several interatomic distances. For ungrounded bodies they spread over the area of the contact layer, and for those connected to the ground loop they flow onto it.

The acquisition of static charges by the body and their drainage occur simultaneously. Electrification is ensured when the body receives a greater energy potential than it expends into the external environment.

A practical conclusion follows from this provision: to protect the body from static electricity, it is necessary to remove the acquired charges from it to the ground circuit.

Methods for assessing static electricity

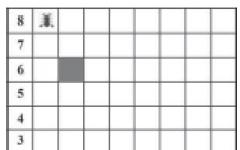

Physical substances, based on their ability to form electrical charges of different signs when interacting with other bodies by friction, are characterized on the scale of the triboelectric effect. Some of them are shown in the picture.

The following facts can be cited as an example of their interaction:

walking in wool socks or shoes with rubber soles on a dry carpet can charge the human body up to 5÷-6 kV;

the body of a car driving on a dry road acquires a potential of up to 10 kV;

the drive belt rotating the pulley is charged up to 25 kV.

As we can see, the potential of static electricity reaches very high values even in living conditions. But it does not cause us much harm because it does not have high power, and its discharge passes through the high resistance of the contact pads and is measured in fractions of a milliamp or a little more.

In addition, it is significantly reduced by air humidity. Its influence on the amount of body tension in contact with various materials shown in the graph.

From his analysis, the conclusion follows: in a humid environment, static electricity appears less. Therefore, various air humidifiers are used to combat it.

In nature, static electricity can reach enormous values. When clouds move over long distances, significant potentials accumulate between them, which manifest themselves as lightning, the energy of which is enough to split a century-old tree along the trunk or burn down a residential building.

When static electricity is discharged in everyday life, we feel “tingling” in our fingers, see sparks emanating from woolen items, and feel a decrease in vigor and efficiency. The current to which our body is exposed in everyday life has a negative impact on our well-being and condition. nervous system, but it does not cause obvious, visible damage.

Manufacturers of industrial measuring equipment produce instruments that make it possible to accurately determine the voltage value of accumulated static charges both on equipment housings and on the human body.

How to protect yourself from static electricity at home

Each of us must understand the processes that create static discharges that pose a threat to our body. They should be known and limited. For this purpose, various educational events are held, including popular television programs for the population.

They show, using accessible means, methods for creating static voltage, principles for measuring it, and methods for performing preventive measures.

For example, given the triboelectric effect, it is best to use combs made of natural wood, and not metal or plastic, as most people do. Wood has neutral properties and does not form charges when rubbed against hair.

To remove static potential from the car body when driving on a dry road, use special antistatic tapes attached to the bottom. Various types of them are widely available on sale.

If there is no such protection on the car, then the voltage potential can be removed by briefly grounding the body through a metal object, for example, a car ignition key. It is especially important to perform this procedure before refueling.

When a static charge accumulates on clothing made of synthetic materials, it can be removed by treating the vapors from a special canister containing “Antistatic” composition. In general, it is better to use such fabrics less and wear natural materials made from linen or cotton.

Shoes with rubberized soles also contribute to the accumulation of charges. It is enough to put antistatic insoles made of natural materials into it, and the harmful effects on the body will be reduced.

The influence of dry air, characteristic of city apartments in winter time, has already been discussed. Special humidifiers or even small pieces of dampened cloth placed on the battery improve the situation and reduce the formation of static electricity. But regular wet cleaning of premises allows you to promptly remove electrified particles and dust. This is one of the best ways protection.

Household electrical appliances also accumulate static charges on their bodies during operation. A potential equalization system connected to the general grounding loop of the building is designed to reduce their impact. Even a simple acrylic bathtub or an old cast-iron structure with the same insert is susceptible to static and requires protection in a similar way.

How to protect against static electricity in production

Factors that reduce the performance of electronic equipment

Discharges that occur during the manufacture of semiconductor materials can cause great harm, disrupt the electrical characteristics of devices, or even disable them.

In production conditions, the discharge can be random and depend on a number of different factors:

the size of the formed capacity;

energy potential;

electrical resistance of contacts;

type of transient processes;

other accidents.

In this case, at the initial moment of about ten nanoseconds, the discharge current increases to a maximum, and then it decreases within 100÷300 ns.

The nature of the occurrence of a static discharge on a semiconductor device through the operator’s body is shown in the picture.

The magnitude of the current is influenced by: the charge capacity accumulated by a person, the resistance of his body and contact pads.

During the production of electrical equipment, a static discharge can be created without operator participation due to the formation of contacts through grounded surfaces.

In this case, the discharge current is affected by the charge capacity accumulated by the device body and the resistance of the formed contact pads. In this case, the semiconductor is initially simultaneously affected by the induced high voltage potential and the discharge current.

Due to this complex effect, damage can be:

1. obvious, when the performance of the elements is reduced to such an extent that they become unsuitable for use;

2. hidden - due to a reduction in output parameters, sometimes even falling within the established factory characteristics.

The second type of malfunction is difficult to detect: they most often result in loss of performance during operation.

An example of such damage from the action of high static voltage is demonstrated by graphs of the deviation of the current-voltage characteristics in relation to the KD522D diode and the integrated circuit BIS KR1005VI1.

The brown line numbered 1 shows the parameters of semiconductor devices before testing with increased voltage, and curves numbered 2 and 3 show their decrease under the influence of an increased induced potential. In case #3 it has a greater impact.

Damage may be caused by:

excessive induced voltage, which breaks through the dielectric layer of semiconductor devices or disrupts the structure of the crystal;

high density of flowing current, causing high temperatures, leading to melting of materials and burning of the oxide layer;

tests, electrical and thermal training.

Hidden damage may not affect performance immediately, but after several months or even years of operation.

Methods for implementing protection against static electricity in production

Depending on the type of industrial equipment, one of the following methods of maintaining operability or a combination of them is used:

1. eliminating the formation of electrostatic charges;

2. blocking their entry into the workplace;

3. increasing the resistance of devices and components to the action of discharges.

Methods No. 1 and No. 2 allow you to protect a large group of different devices in a complex, and No. 3 is used for individual devices.

High efficiency in maintaining the operability of the equipment is achieved by placing it inside a Faraday cage - a space fenced on all sides with a fine-mesh metal mesh connected to a ground loop. External electric fields do not penetrate inside it, but static magnetic fields are present.

Cables with a shielded sheath work on this principle.

Static protection is classified according to the principles of execution into:

physical and mechanical;

chemical;

structural and technological.

The first two methods allow you to prevent or reduce the formation of static charges and increase the rate of their drainage. The third technique protects devices from the effects of charges, but it does not affect their drainage.

The drainage of discharges can be improved by:

creation of coronation;

increasing the conductivity of materials on which charges accumulate.

These issues are resolved:

air ionization;

increasing working surfaces;

selection of materials with better volumetric conductivity.

Due to their implementation, lines prepared in advance are created to drain static charges onto the ground loop, preventing them from reaching the working elements of devices. It is taken into account that the total electrical resistance of the created path should not exceed 10 Ohms.

If materials have high resistance, then protection is performed in other ways. Otherwise, charges begin to accumulate on the surface, which can be discharged upon contact with the ground.

An example of complex electrostatic protection of a workplace for an operator involved in the maintenance and adjustment of electronic devices is shown in the picture.

The table surface is connected to the ground loop through a connecting conductor and a conductive mat using special terminals. The operator works in special clothing, wears shoes with conductive soles and sits on a chair with a special seat. All these measures make it possible to efficiently discharge accumulated charges to the ground.

Working air ionizers regulate humidity and reduce the potential of static electricity. When using them, it is taken into account that the increased content of water vapor in the air negatively affects human health. Therefore, they try to maintain it at a level of about 40%.

Also effective way There may be regular ventilation of the room or the use of a ventilation system in it, when the air passes through filters, is ionized and mixed, thus ensuring the neutralization of emerging charges.

To reduce the potential accumulated by the human body, bracelets can be used to complement a set of antistatic clothing and shoes. They consist of a conductive strip that is attached to the arm using a buckle. The latter is connected to the ground wire.

With this method, the current flowing through the human body is limited. Its value should not exceed one milliamp. Larger values may cause pain and electrical injuries.

As the charge flows to the ground, it is important to ensure that it leaves at a rate of one second. For this purpose, floor coverings with low electrical resistance are used.

When working with semiconductor boards and electronic units Protection against damage from static electricity is also provided by:

forced shunting of the terminals of electronic boards and units during checks;

using tools and soldering irons with grounded working heads.

Containers with flammable liquids located on vehicles are grounded using a metal circuit. Even the fuselage of the aircraft is equipped with metal cables, which act as protection against static electricity during landing.

On dielectric materials, after they rub against each other or against metal objects, electric charges of increased density are formed. Thus, static electricity occurs, against which protective measures are absolutely necessary. First of all, this is due to the slow disappearance of charge due to the fact that dielectrics have extremely low electrical conductivity.

The appearance and danger of static electricity

The cause of electrification can also be induction. An electric charge with an opposite value appears on the metal surface, the density of which is uniform in all places. The conditions for this phenomenon to occur can be very different. Often the cause is the pumped liquid moving through pipelines or in the form of a falling jet. The same effect is achieved by compressed or liquefied gases, the operation of belt drives, grinding and processing of organic and polymeric materials.

Electrification of dielectric materials often reaches a potential difference with high voltage. For example, during the process of pumping gasoline using a pipeline with an isolated section, electrical potentials can fluctuate between 1460 and 14600 volts.

The accumulation of static electricity is a serious danger. In such cases, a strong spark discharge often appears. The released spark energy with a value of 0.01 J is already capable of causing a fire and explosion. A voltage of 300 volts results in an air spark discharge. Taking timely special measures helps prevent the consequences of electrical discharges.

Protective measures against static electricity

To equalize potentials and prevent sparks, all pipelines located in parallel, at a distance of less than 100 mm, are connected by jumpers every 20-25 meters. Piping and equipment systems must be grounded in at least two places. Checking for grounding is carried out using a tester or once every 6 months and after repair work.

During loading, pumping and transportation of petroleum products, the resulting electrostatic discharges are removed by metallic connections between pumps, pipelines, tanks and other devices. In case of spillage of dielectric liquids into vessels made of glass and other insulating materials, it is necessary to use funnels made of electrically conductive materials. They are grounded and connected by copper cables to supply hoses. Each funnel should reach the bottom of the vessel. If this is not possible, then a grounded cable is passed through the funnel, reaching the bottom, along which the liquid will flow.

It should be remembered that maximum electrification occurs in pipes made of low-carbon steel. If there is a rough surface, static electricity appears, measures to protect against it include eliminating the turbulence of the liquid that occurs during movement. To enhance electrification, the most necessary favorable conditions, arising in certain places. Areas with less suitable conditions contribute to the loss of charges in the electrified liquid or their retention at the same level.

The loading pipe must reach the bottom when filling the container. The loading hole must have a large cross-section so that the jet cannot come into contact with the walls and surface of the liquid being poured. If these conditions cannot be met, it is necessary to reduce the loading speed as much as possible, bringing it to 0.5-0.7 m/s. Taken measures will guarantee to avoid unpleasant consequences.